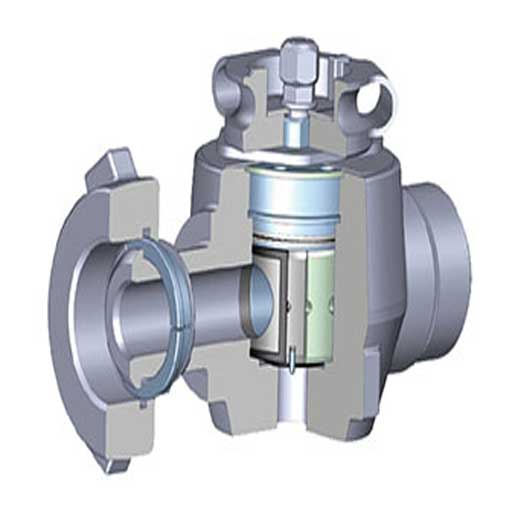

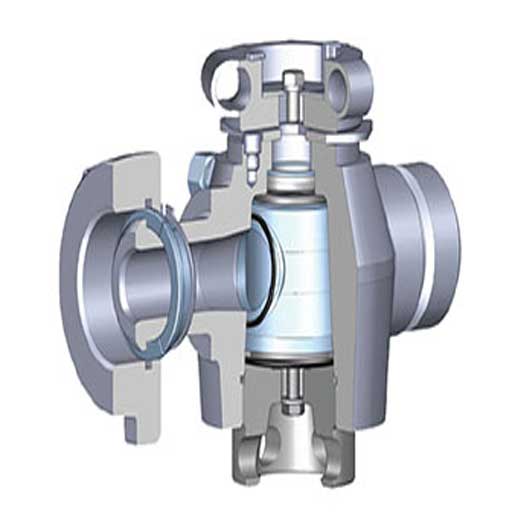

The ball of the ball valve is floating. Under the action of the medium pressure, the ball can generate a certain displacement and press on the sealing surface at the outlet end to ensure the sealing of the outlet end.

The floating ball valve has a simple structure and good sealing performance, but the load of the ball subjected to the working medium is all transmitted to the outlet sealing ring, so it is necessary to consider whether the sealing ring material can withstand the working load of the spherical medium, and when subjected to a high-pressure impact The sphere may be offset. This structure is generally used for medium and low-pressure ball valves.

The main features of the ball valve are its compact structure, reliable sealing, simple structure and convenient maintenance. The sealing surface and the spherical surface are often closed, not easily eroded by the medium, easy to operate and maintain, suitable for general work such as water, solvent, acid and natural gas. Medium, but also suitable for medium with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene, which are widely used in various industries. The ball valve body may be integral or combined.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română