Pump Barrel for Sucker Rod Pump:

Specification:Φ32、Φ38、Φ44、Φ57、Φ70、Φ83、Φ95、Φ108 、Φ120、Φ140 and non-certificated models.

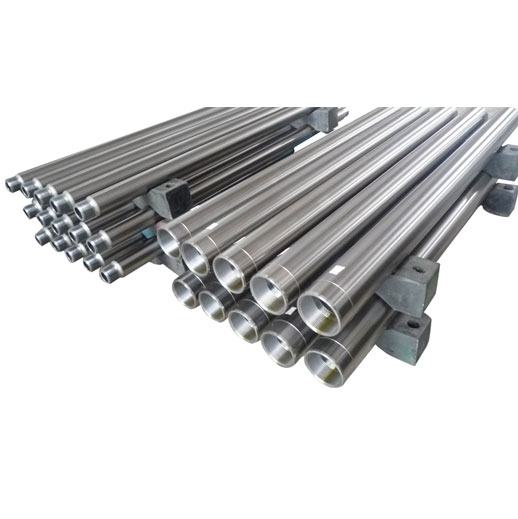

Pump Plunger for Sucker Rod Pump:

Specification:Φ32、Φ38、Φ44、Φ57、Φ70、Φ83、Φ95、Φ108 and non-certificated models.

Complete line of spray metal plungers with the hardest most corrosion resistant metals available. Each plunger and/or plunger component must meet corresponding metallurgical and precision standards, as well as the dimensional standards of API 11AX latest edition.

Specification: 1.1” (φ28mm) –6.3” (φ160mm)

Regular Plunger Length: 1ft-6ft (Can be customized)

The metal spray plunger Using oxygen, acetylene spray welding technology, spray the nickel base alloy powder to pass through the surface of the coarsening and activation of matrix, and then heated to the temperature range of solid liquid phase line to melt and tile alloy materials and get the modified surface welding layer, thus transforming the anti-wear & corrosion performance of the workpiece. The spray metal thickness can be subject to the working condition of the actual requirements, the minimum thickness 0.203mm, welding layer and base metal metallurgy brazing, the bonding strength can be up to 200 ~ 300 Mpa. The Nickel base alloy powder and base has good bonding strength, better shock resistance, higher hardness, wear & corrosion resistance, anti-oxidation can be up to 650 ℃, which can make good friction pair with pump barrel.

Nitriding is a heat-treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. Nitriding Plunger applies gas nitriding surface hardening process, where nitrogen is added to the surface of plunger using dissociated ammonia as the source. The nitriding plunger increases wear resistance, surface hardness, fatigue limit and corrosion resistance.

Structure:

Equal diameter plunger is composed of upper and lower equal diameter connector, plunger and traveling valve cage.

Type:

1. Long plunger connected by a 1.2m or 1.5m long short plunger

2. Integral long plunger with metal spray, straightening and whole grinding

Features:

The outer surface is adopted metal spray technology, which can ensure that the plunger has the characteristics of corrosion resistance, wear resistance and size stability for a long time.

The long plunger with high precision size, good straightness and concentricity, small flow resistance coefficient and smooth surface, is not easy to scale and stuck pump.

Sand control, sand control grinding, effectively extend the production cycle of oil wells.

Low price, high efficiency.

The long plunger sand pump with short pump barrel, Long plunger, sinking sand and lateral inlet structure is a more widely used sand control pump, through up and down strokes of plunger, the liquid will flow to the ground through duplex connector and double-stage standing valve, at the same time, part of sand that doesn't carrying up in the tubing string will sink into the grit tail pipe through the annulus between pump barrel and grit tube as well as duplex connector.

Chrome-plated Pump Barrel

The chrome internally plated barrel is fabricated from carefully selected carbon steel material and has a uniform thickness of chrome plating is added on the I.D., offering resistance to abrasive sands and foreign materials. It has exacting tolerances conforming to API dimensions.

Uniform plating, high bonding strength, accurate dimensional precision

The inner bore hardness up to HV900-1160, small friction coefficient and good wear resistance, can be used for sand and other friction medium oil Wells

Good chemical stability, no action in alkali, sulfide, nitric acid and most organic acids, and excellent corrosion resistance

Subsurface Pump Cage

The subsurface pump cages have been designed to give maximum flow capability. The cage crown has been scientifically designed to provide the correct ball lift and provide the correct side clearance to ensure free and unobstructed fluid flow through the valve.

A variety of materials: Carbon steel 1045, Alloy-steel 4130(30CrMo), 4135(35CrMo), 5140(40Cr) Stainless Steel 304, 316L, Monel 400, etc. are offered to tailor the cage to meet specific well requirements and API 11AX Standard Latest Edition.

Barrel specification | Nominal Dia.mm(in) | I.D. Tolerance (mm) | Wall thickness | Material | Plunger specification | O.D. Tolerance (mm) | Length |

Φ32 | 31.75mm/11/4” | ±0.05 | 1.5mm/ 3/50” 3.18mm/ 1/8” 6.35mm/ 1/4” 9.53mm/ 3/8” 19.05mm/ 3/4” 22.23mm/ 7/8” 25.4mm/ 1” 1” | Carbon Steel Pipe Brass Pipe Alloy Steel Pipe | Φ32 | ±0.05 | 1.2m-1.8m 4’-6’ |

Φ38 | 38.10mm/11/2” | ±0.05 | Φ38 | ±0.05 | |||

Φ44 | 44.45mm/13/4” | ±0.05 | Φ44 | ±0.05 | |||

Φ50 | 50.8mm/2” | ±0.05 | Φ50 | ±0.05 | |||

Φ57 | 57.15mm/2 1/4” | ±0.05 | Φ57 | ±0.05 | |||

Φ70 | 69.85mm/2 3/4” | ±0.10 | Φ70 | ±0.10 | |||

Φ83 | 82.55mm/3 1/4” | ±0.10 | Φ83 | ±0.10 | |||

Φ95 | 95.25mm/3 3/4” | ±0.10 | Φ95 | ±0.10 | |||

Φ108 | 107.95mm/4 1/4” | ±0.10 | Φ108 | ±0.10 | |||

Φ220 | 219.75mm | ±0.10 | Φ220 | ±0.10 |

Specification | Nominal Dia. | Tolerance | Wall Thickness | Material |

Φ139 | 139.7mm/ | ±0.05mm | 3.18mm/ | Alloy steel pipe (16Mn,1Cr5Mo,35CrMo,9Cr1Mo,13Cr,22Cr, A335P9,4130, K500,718) |

5 1/2” | 1/8” | |||

Φ178 | 177.8mm/7” | ±0.05mm | 6.35mm/ | |

1/4” | ||||

Φ210 | 209.55mm/8-1/2” | ±0.05mm | 9.53mm/ | |

3/8” |

Size (mm) | Plunger Length (mm) |

1-1/4” (φ32) | 600/ 900/1200 /1500 /4500 |

1-1/2” (φ38) | |

1-3/4” (φ44) | |

2-1/4” (φ57) | |

2-3/4” (φ70) | |

3.27” (φ83) | |

3-3/4” (φ95) |

Size (mm) | Plunger Length |

1.1” (φ28) | 2.4m~12m |

1-1/4” (φ32) | |

1-1/2” (φ38) | |

1-3/4” (φ44) | |

2-1/4” (φ57) | |

2-3/4” (φ70) | |

3.27” (φ83) | |

3-3/4” (φ95) |

Size in(mm) | Length |

1.1” (φ28) | 1.2~10.9m 4’~36’ |

1-1/4” (φ32) | |

1-1/2” (φ38) | |

1-3/4” (φ44) | |

2-1/4” (φ57) | |

2-3/4” (φ70) | |

3.27” (φ83) | |

3-3/4” (φ95) | |

4-3/4” (φ120) | |

5-1/2” (φ140) | |

6.3” (φ160) |

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română