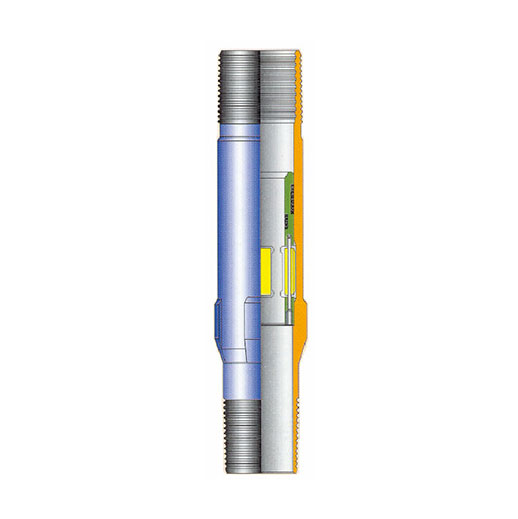

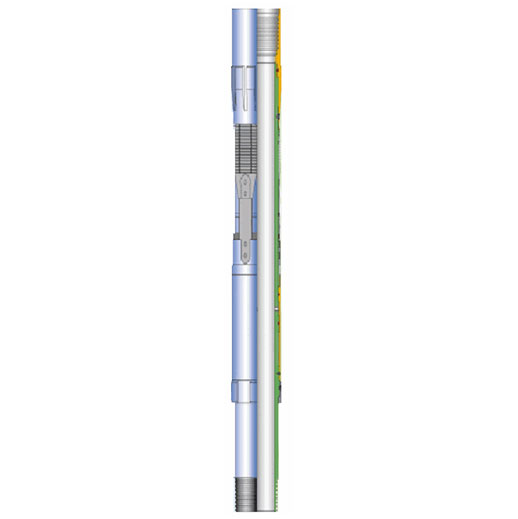

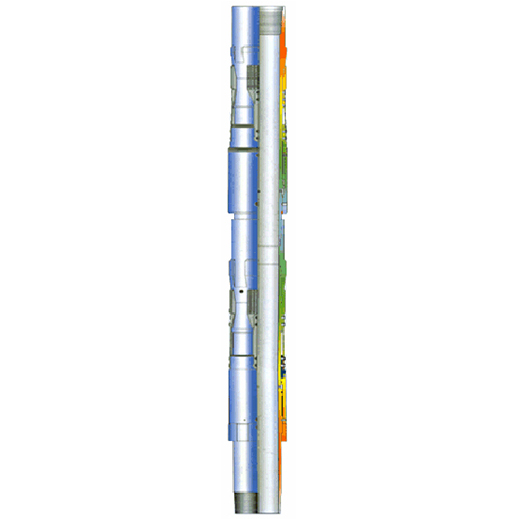

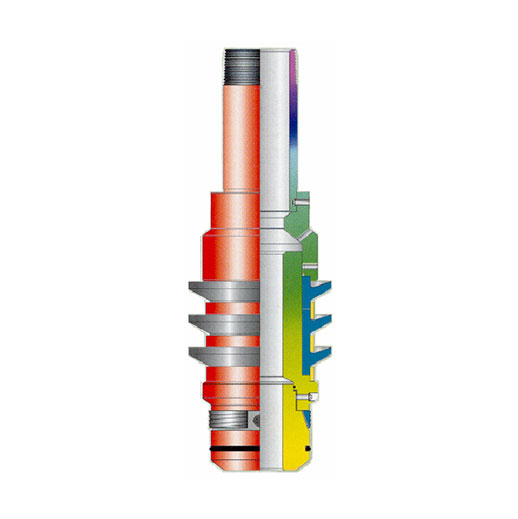

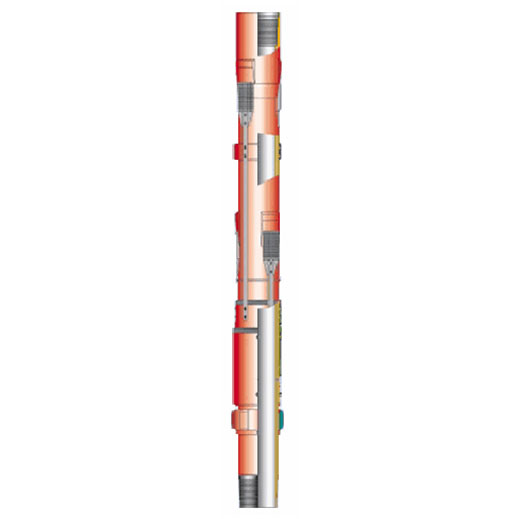

The liner cementing is realized by the liner hanger, which reduces the casing weight of the first well in the deep well, improves the load of the rig lifting system when the casing is cut, and reduces the flow resistance of the cement slurry, which is beneficial to safe construction. Through the liner connection, the problem of drilling operation due to the wear of the upper casing can be solved; using the liner suspension cementing technology can also reduce the amount of casing and save the drilling cost.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română