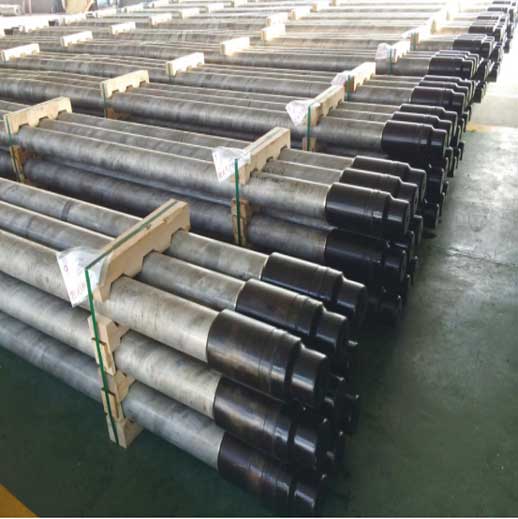

The drill pipe is a steel pipe with a tail thread for connecting the surface equipment of the drilling rig and the drilling equipment or bottom hole device at the bottom of the drilling. The purpose of the drill pipe is to transport the drilling mud to the drill bit and to raise, lower or rotate the bottom hole device with the drill bit. The drill pipe must be able to withstand large internal and external pressures, distortions, bends and vibrations. The drill pipe can be used multiple times during the oil and gas extraction and refining process. The drill pipe is divided into three types: a square drill pipe, a drill pipe and a weighted drill pipe. The connection sequence is kelly + drill pipe (n, determined by well depth) + weighted drill pipe (n, determined by the drill combination design). The classification of the drill pipe, the drill pipe joint, the drill pipe specifications, and the steel grade and strength of the drill pipe are detailed.

The usual components of the drill string are: drill bits, drill collars, drill pipes, stabilizers, special joints and kelly bars.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română