Valve actuators are an essential part of an automated control system. Its function is to accept the control signal sent by the controller and change the size of the controlled medium to maintain the controlled variable at the required value or within a certain range.

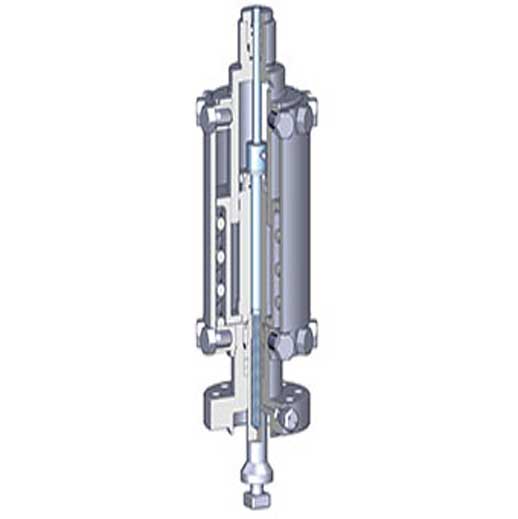

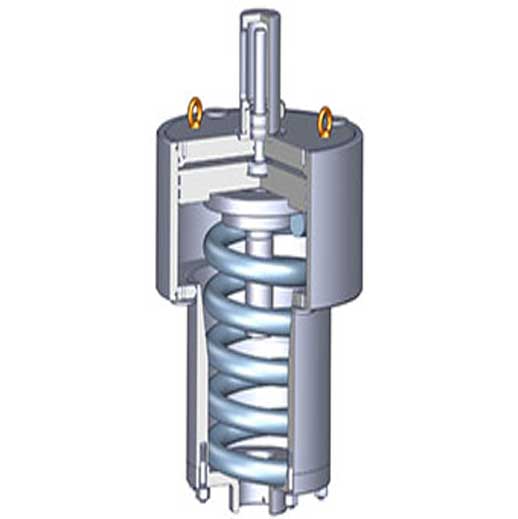

Actuators can be divided into three categories according to their energy form: pneumatic, hydraulic and electric. Pneumatic actuators use compressed air as an energy source, which is characterized by simple structure, reliable and stable operation, large output thrust, convenient maintenance, fireproof and explosion-proof, and low price.

Therefore, it is widely used in chemical, papermaking, oil refining and other production processes. It can be easily used with passive instruments. Even when using an electric meter or computer control, a pneumatic actuator can be used as long as the electrical signal is converted to a standard pressure signal of 20-100 kPa via an electro-pneumatic converter or an electro-pneumatic valve positioner. Electric actuators are easy to use and have fast signal transmission, but the structure is complex and the explosion-proof performance is poor. The hydraulic actuator is basically not used in the production process of the chemical industry, oil refining, etc. It is characterized by a large output thrust.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română