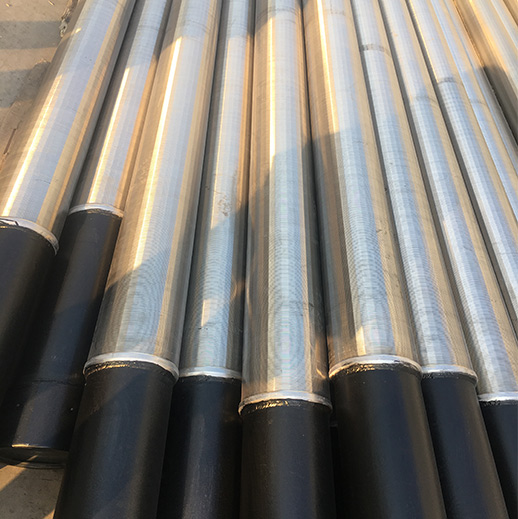

The slotted pipes using in oil exploration can prevent 99% sand, decrease 80% of oil well heavy repair and increase the oil well's strength, integrality and stability of keeping off sand. Meanwhile, the laser incision can make very small cuts with smooth surface and high precision. Although its structure is simple, it is very effective. It has small cuts of 0.10-0.5 mm in the tube wall.

The slotted liner is a robust and cost-effective solution for long completions or low productivity wells.

We offer straight and key stone slot in a wide range of slotting patters to satisfy the required open area.

High rigidity resisting scrape and abrasion, high intensity, anti-corrosion and even distribution.

Material: stainless steel, carbon steel

Categories of pipes: petroleum casing pipe, oil pipe

Length of pipe (single): ≤15m

Outside diameter of pipe: 50 to 200mm

Wall thickness ≤16mm

Width of slot: (0.10-0.40)mm±0.03mm

Number of slots: according to order

Distribution types of slots: parallel, crisscross, spiral

Distance of slots: according to order

The perforated pipe with cutting edge technology, which is manufactured carbon steel or stainless steel, used for the application of oil reservation layer without much sand or for application of prevents the rock bits dropping off the well bore.

Features:

Every joint perforated by us is deburred internally and externally.

Each hole is visually inspected and burr cleaned.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română