Industrial ceramics, that is, ceramics for industrial production and industrial products. It is a type of fine ceramics, which can play mechanical, thermal, chemical and other functions in applications. Because industrial ceramics have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance, erosion resistance, etc., they can replace metal materials and organic polymer materials in harsh working environments, and have become a medium for traditional industrial transformation, emerging industries and high-tech. It is an indispensable important material and has a very broad application prospect in the fields of energy, aerospace, machinery, automobile, electronics, chemical industry and so on. Use corrosion-resistant, chemically stable ceramics in contact with biological enzymes to produce metal crucibles, heat exchangers, biological materials such as dental artificial paint joints, etc., and use unique neutron capture and absorption ceramics to produce various nuclear Reactor structural materials, etc.

Ordinary ceramics refers to clay ceramics, which are fired from clay, feldspar, and quartz. Its performance depends on the purity, particle size and proportion of the three raw materials. Generally, the texture is hard, corrosion-resistant, non-oxidizing, non-conductive, able to withstand a certain high temperature and has good formability.

Application

Industrial ordinary ceramics are mainly used for electrical porcelain for insulation, chemical porcelain with high acid and alkali requirements, and porcelain for structural parts with low bearing requirements, such as insulators, corrosion-resistant containers, pipes and decorative porcelain and tableware in daily life. Wait.

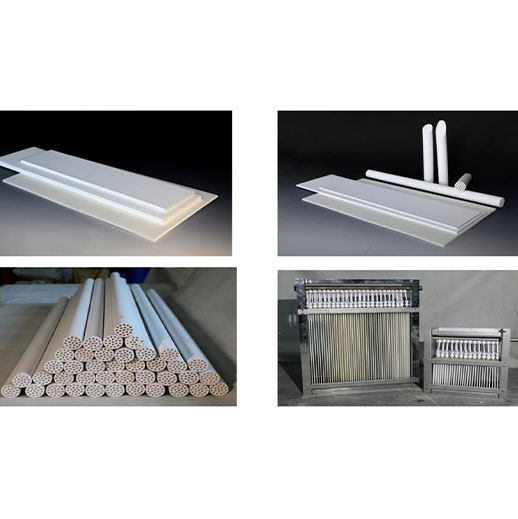

The ceramic is a ceramic with AL2O3 as the main component (the mass fraction of AL2O3 is >45%). According to the difference of the main crystal phase in the porcelain blank, it can be divided into corundum porcelain, corundum-mullite porcelain and mullite porcelain, etc.; It can be divided into 75 porcelain, 95 porcelain and 99 porcelain according to the mass fraction of AL2O3.

Application

Alumina porcelain has high melting point, high hardness, high strength, and good chemical corrosion resistance and dielectric properties. However, it is brittle, has poor impact resistance and thermal shock resistance, and cannot withstand drastic changes in ambient temperature. It can be used to manufacture furnace tubes, furnace linings, and spark plugs of internal combustion engines for high-temperature furnaces. It can also be used to manufacture high-hardness cutting tools.

The biggest feature of silicon carbide ceramics is high temperature strength, high thermal conductivity, high wear resistance, corrosion resistance and creep resistance. High-temperature parts such as nozzles of rocket tail nozzles, nozzles for pouring metal, thermowells, furnace tubes, etc.

Application

Due to its high thermal conductivity, it can also be used to manufacture high-temperature strength parts such as blades and bearings of gas turbines, as well as materials for high-temperature heat exchangers and encapsulation materials for nuclear fuel.

The main crystal phases of lithium oxide ceramic products are eucryptite (Li2O·Al2O3·2SiO2) and spodumene (Li2O·Al2O3·4SiO2), which are characterized by low thermal expansion coefficient (-0.03×10/ ℃~ 4.08×10/℃), good thermal shock resistance. Li2O is an out-of-network oxide, which can strengthen the glass network and effectively improve the chemical stability of the glass.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română