Shandong Saigao Group Corporation sells large forgings and large castings, has many years of experience in the supply of forgings and castings, and exports to more than 50 countries and regions in the world.

Saigao's large metal fabrication production equipment & capabilities include: Melting (EAF – LF - VD/VOD), Casting (Iron Casting), Forging (12000t/5000t/3150t/1250t Forging Press), Heat treatment, Machining, and Surface treatment.

Main shaft for wind turbine

Hub, main Frame, Bearing House for Wind Turbine

Pipe Mould for ductile casing pipe

Rotor shaft for Turbine/Generators

Forgings for pressure vessels

Shipping building forgings/Vessel forging parts

Cold Roller, Support Roller

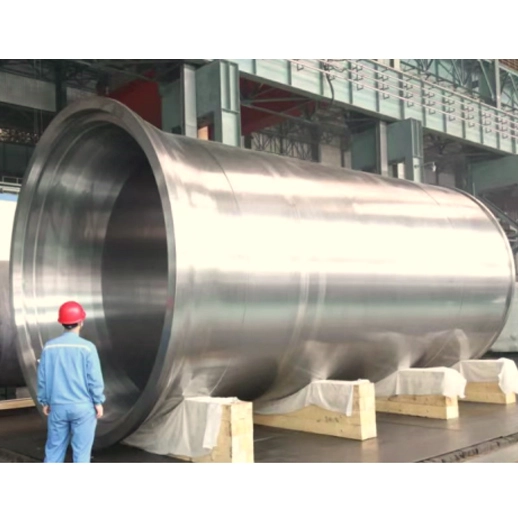

Forgings for the Cement Industry/Mining Industry

Large forgings are objects in which metal is pressed to form the required shape or suitable compression force through plastic deformation. Strength is typically achieved through the use of a hammer or pressure. The casting process creates a refined grain structure and improves the physical properties of the metal.

In the actual use of components, a correct design can make the particle flow in the direction of the main pressure. The manufacture of large forgings is one of the key technologies for major equipment manufacturing. Its quality directly affects the overall level and operational reliability of major equipment. It is the basis for the development of industries such as electric power, shipbuilding, metallurgy, petrochemicals, heavy machinery, and national defense. And it is a prerequisite for the advanced equipment manufacturing industry. With the continuous development of China's equipment manufacturing industry, the demand for large and large forgings will continue to expand.

Oversized forgings are the classification of forgings, large tonnage, and large-size forgings, including rings, shafts, cakes, and other forgings. Forgings need to be consistent from piece to piece, without any porosity, excess space, inclusions, or other blemishes. Components produced by this method have a high ratio of strength to weight. Components are commonly used in aircraft construction. The advantages of forgings are stretchable length, shrinkable cross section; shrinkable length, stretchable cross section; changeable length, and changeable cross section. The types of forgings are free forging/hand forging, hot die forging/precision forging, top forging, rolling forging, and die forging.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română