Aluminum drill pipe has the advantage of low density, high strength, corrosion and fatigue resistance, good processing performance and excellent low temperature toughness. It is a promising technique to solve the drilling problems arising from complex working conditions of the deep and super deep well, horizontal well, extended reach well, sour well and offshore well etc. As it can improve the efficiency and safety of drilling, the technique of aluminum drill pipe is significant important. The feature and process of aluminum drill pipe in recent years are reviewed. Some proposals for the application of aluminum drill pipe in China oil and gas industry are also provided.

Aluminum alloy drill pipe has outstanding advantages such as low density, high strength, corrosion resistance, fatigue resistance, processing performance and low temperature plastic toughness. It is used to solve deep wells, ultra deep wells, horizontal wells, large displacement wells and sulfur-containing conditions under complex working conditions. Drilling problems such as wells and offshore oil have broad application prospects. Studying aluminum alloy drill pipe technology, improving drilling efficiency, ensuring drilling safety, and having high scientific research value. Combined with the characteristics of aluminum alloy drill pipe technology, it introduces domestic and foreign development and application. Dynamic, indicating the future application direction of aluminum alloy drill pipe in China's oil and gas industry.

Aluminum Alloy Drill Pipe Mechanical Properties

Non-magnetic Heavy Aluminum Alloy Drill Pipe(Replacement of non-magnetic drill collar ) Properties

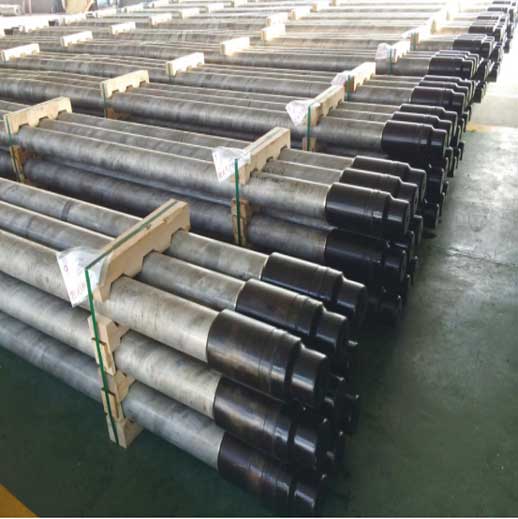

Heavy-wall Aluminum Alloy Drill Pipe with Spiral Groove

Thick-walled Aluminum Alloy Drill Pipe

Nominal outside diameter, mm | Nominal wall thickness,mm | Upset type | Connection | TJ torsional yield strengthf, kN·m | Tension yield strengtha, kN | Torsional yield strengthb, kN·m | Internal yield pressurec, MPa | Collapse pressured, MPa | P/N | ||||||||||||||

TJ thread type | TJ OD, mm | TJ pin OD, mm | Material groupe | Material groupe | Material groupe | Material groupe | |||||||||||||||||

I | II | III | IV | I | II | III | IV | I | II | III | IV | I | II | III | IV | ||||||||

64 | 8 | IU | NC 23 | 80 | 34 | 8.2 | 457 | 675 | 478 | 492 | 5.2 | 7.7 | 5.5 | 5.6 | 81.3 | 120 | 85 | 87.5 | 72.9 | 104.4 | 76.1 | 78.2 | SG-64-IU-NC23 |

73 | 9 | IU | NC 26 | 95 | 44 | 10 | 588 | 868 | 615 | 633 | 7.7 | 11.4 | 8.1 | 8.3 | 80.1 | 118.4 | 83.8 | 86.3 | 71.7 | 102.5 | 74.8 | 76.9 | SG-73-IU-NC26 |

90 | 8 | EU | NC 38 | 118 | 68 | 21.8 | 669 | 989 | 700 | 721 | 11.6 | 17.1 | 12.1 | 12.5 | 57.8 | 85.3 | 60.4 | 62.2 | 46.9 | 63 | 48.7 | 49.8 | SG-90-EU-NC38 |

90 | 9 | IU | NC 31 | 108 | 54 | 16.1 | 744 | 1099 | 778 | 801 | 12.6 | 18.6 | 13.2 | 13.5 | 65 | 96 | 68 | 70 | 55.2 | 76.3 | 57.4 | 58.9 | SG-90-IU-NC31 |

IU | NC 38 | 120.6 | 58 | 25.8 | SG-90-IU-NC38 | ||||||||||||||||||

103 | 9 | IU | NC 38 | 120.6 | 68 | 24.7 | 863 | 1275 | 903 | 930 | 17.1 | 25.3 | 17.9 | 18.4 | 56.8 | 83.9 | 59.4 | 61.2 | 45.7 | 61.2 | 47.4 | 48.5 | SG-103-IU-NC38-120 |

IU | NC 38 | 127 | 68 | 25 | SG-103-IU-NC38-127 | ||||||||||||||||||

114 | 10 | IU | NC 44 | 145 | 82 | 35.7 | 1061 | 1567 | 1110 | 1143 | 23.3 | 34.4 | 24.3 | 25.1 | 57 | 84.2 | 59.6 | 61.4 | 46 | 61.6 | 47.7 | 48.8 | SG-114-IU-NC44 |

EU | NC 50 | 155 | 95 | 49.9 | SG-114-EU-NC50 | ||||||||||||||||||

114 | 11 | IU | NC46 | 152 | 80 | 48.5 | 1156 | 1708 | 1210 | 1245 | 24.9 | 36.8 | 26.1 | 26.8 | 62.7 | 92.6 | 65.6 | 67.5 | 52.6 | 72.1 | 54.7 | 56 | SG-114-IU-NC46 |

129 | 9 | EU | 5 1/2 FH | 172 | 112 | 55.4 | 1102 | 1628 | 1153 | 1187 | 28.3 | 41.8 | 29.6 | 30.5 | 45.3 | 67 | 47.4 | 48.8 | 31.8 | 39.6 | 32.7 | 33.3 | SG-129-EU-5 1/2 FH |

129 | 11 | IU | NC 50 | 162 | 95 | 51.3 | 1325 | 1956 | 1386 | 1427 | 33 | 48.8 | 34.6 | 35.6 | 55.4 | 81.9 | 58 | 59.7 | 44.1 | 58.6 | 45.7 | 46.8 | SG-129-IU-NC50 |

131 | 13 | EU | 5 1/2 FH | 178 | 105 | 69.4 | 1565 | 2312 | 1638 | 1686 | 38.6 | 57 | 40.3 | 41.5 | 64.5 | 95.3 | 67.5 | 69.5 | 54.6 | 75.4 | 56.8 | 58.3 | SG-131-EU-5 1/2 FH |

133 | 11 | EU | 5 1/2 FH | 172 | 112 | 55.4 | 1370 | 2023 | 1433 | 1475 | 35.4 | 52.3 | 37 | 38.1 | 53.8 | 79.4 | 56.2 | 57.9 | 42.1 | 55.5 | 43.6 | 44.6 | SG-133-EU-5 1/2 FH |

140 | 13 | EU | 5 1/2 FH | 172 | 112 | 55.4 | 1685 | 2488 | 1763 | 1814 | 44.9 | 66.3 | 47 | 48.4 | 60.4 | 89.1 | 63.1 | 65 | 49.9 | 67.8 | 51.8 | 53.1 | SG-140-EU-5 1/2 FH |

147 | 11 | IU | 5 1/2 FH | 178 | 105 | 69.4 | 1527 | 2255 | 1597 | 1644 | 44.3 | 65.4 | 46.3 | 47.7 | 48.6 | 71.8 | 50.9 | 52.4 | 35.9 | 45.8 | 37.1 | 37.8 | SG-147-11-IU-5 1/2 FH |

EU | 6 5/8 FH | 195 | 124 | 84.5 | SG-147-11-EU-5 1/2 FH | ||||||||||||||||||

147 | 13 | IU | 5 1/2 FH | 178 | 105 | 69.4 | 1778 | 2626 | 1860 | 1914 | 50.2 | 74.1 | 52.5 | 54.1 | 57.5 | 84.9 | 60.1 | 61.9 | 46.5 | 62.5 | 48.3 | 49.4 | SG-147-13-IU-5 1/2 FH |

147 | 13 | IU | 4 1/2 IF | 178 | 105 | 69.4 | 1778 | 2626 | 1860 | 1914 | 50.2 | 74.1 | 52.5 | 54.1 | 57.5 | 84.9 | 60.1 | 61.9 | 46.5 | 62.5 | 48.3 | 49.4 | SG-147-13-IU-4 1/2IF |

147 | 15 | IU | 5 1/2 FH | 178 | 105 | 69.4 | 2021 | 2984 | 2114 | 2176 | 55.6 | 82.1 | 58.1 | 59.8 | 66.3 | 98 | 69.4 | 71.4 | 56.7 | 78.7 | 59 | 60.5 | SG-147-IU-5 1/2 FH |

151 | 13 | EU | 6 5/8 FH | 195 | 124 | 84.5 | 1831 | 2704 | 1915 | 1972 | 53.3 | 78.8 | 55.8 | 57.5 | 56 | 82.6 | 58.5 | 60.3 | 44.8 | 59.6 | 46.4 | 47.5 | SG-151-EU-6 5/8 FH |

155 | 15 | EU | 6 5/8 FH | 195 | 124 | 84.5 | 2143 | 3165 | 2242 | 2308 | 62.8 | 92.7 | 65.7 | 67.6 | 62.9 | 92.9 | 65.8 | 67.7 | 52.8 | 72.5 | 54.9 | 56.3 | SG-155-EU-6 5/8 FH |

164 | 9 | EU | 6 5/8 FH | 203 | 124 | 107.2 | 1424 | 2103 | 1489 | 1533 | 47.9 | 70.8 | 50.1 | 51.6 | 35.7 | 52.7 | 37.3 | 38.4 | 19.7 | 22.6 | 20.1 | 20.3 | SG-164-EU-6 5/8 FH |

168 | 11 | EU | 6 5/8 FH | 203 | 124 | 107.2 | 1762 | 2603 | 1844 | 1898 | 59.5 | 87.9 | 62.3 | 64.1 | 42.6 | 62.9 | 44.5 | 45.8 | 28.3 | 34.4 | 29.1 | 29.6 | SG-168-11-EU-6 5/8 FH |

IU | 6 5/8 FH | 203 | 127 | 99.5 | SG-168--11-IU-6 5/8 FH | ||||||||||||||||||

168 | 13 | IU | 6 5/8 FH | 203 | 127 | 99.5 | 2056 | 3037 | 2151 | 2214 | 67.8 | 100.2 | 70.9 | 73 | 50.3 | 74.3 | 52.6 | 54.2 | 37.9 | 48.9 | 39.2 | 40 | SG-168--13-IU-6 5/8 FH |

Shandong Saigao Group Corporation(Thick-walled Aluminum Alloy Drill Pipe)

in | ODmm | Wall Thickness tdp mm | Connection | TJ torsional yield strengthf, kN·m | Tensile Yield Strength(KN·m) | Recommended Torque KN·m | P/N | |||||||||||

TJ thread type | TJ OD, mm | TJ pin OD, mm | Body | Body | ||||||||||||||

I | II | III | IV | I | II | III | IV | |||||||||||

3½ | 91 | 20 | NC31 | 108 | 54 | 1449 | 2140 | 1516 | 1561 | 19.8 | 29.3 | 20.8 | 21.4 | 15.5 | SG-91-20-NC31-108 | |||

NC38 | 120.6 | 58 | SG-91-20-NC38-120 | |||||||||||||||

4 | 103 | 20 | NC38 | 120.6 | 68 | 1694 | 2502 | 1772 | 1824 | 27.5 | 40.5 | 28.7 | 29.6 | 15 | SG-103-20-NC38-120 | |||

NC38 | 127 | 68 | SG-103-20-NC38-127 | |||||||||||||||

4½ | 114 | 20 | NC44 | 145 | 82 | 1919 | 2834 | 2007 | 2066 | 35.6 | 52.6 | 37.2 | 38.3 | 29.1 | SG-114-20-NC44-145 | |||

NC46 | 152 | 80 | SG-114-20-NC46-152 | |||||||||||||||

5 | 129 | 22 | NC50 | 162 | 95 | 2402 | 3548 | 2513 | 2587 | 50.9 | 75.2 | 53.2 | 54.8 | 36.1 | SG-129-22-NC50-162 | |||

5⅞ | 147 | 25 | 5½FH | 178 | 105 | 3113 | 4597 | 3256 | 3352 | 75.2 | 111.1 | 78.7 | 81 | 46 | SG-147-25-5 1/2FH-178 | |||

5⅞ | 147 | 25 | 4½IF | 178 | 105 | 3113 | 4597 | 3256 | 3352 | 75.2 | 111.1 | 78.7 | 81 | 46 | SG-147-25-4 1/2IF-178 | |||

6⅝ | 168 | 27 | 6⅝FH | 203 | 127 | 3885 | 5738 | 4064 | 4184 | 109.2 | 161.2 | 114.2 | 117.5 | 59.7 | SG-168-27-6 5/8FH-203 | |||

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română