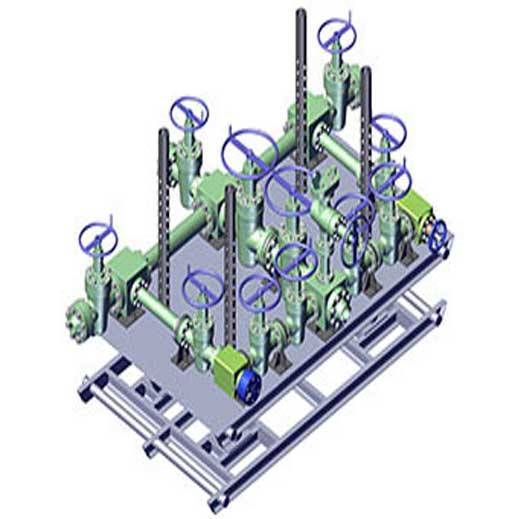

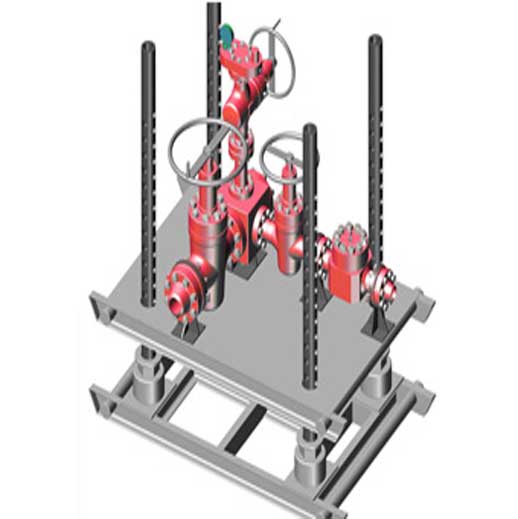

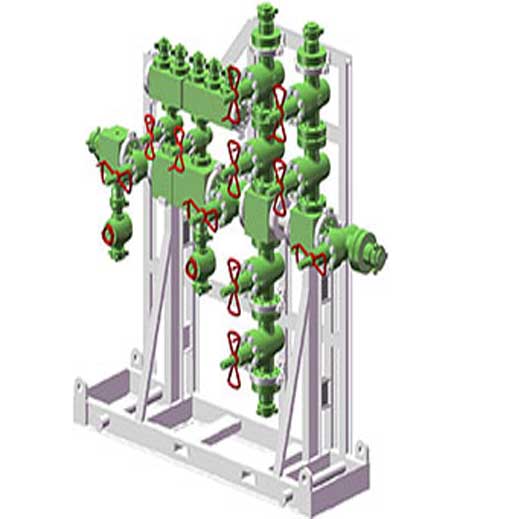

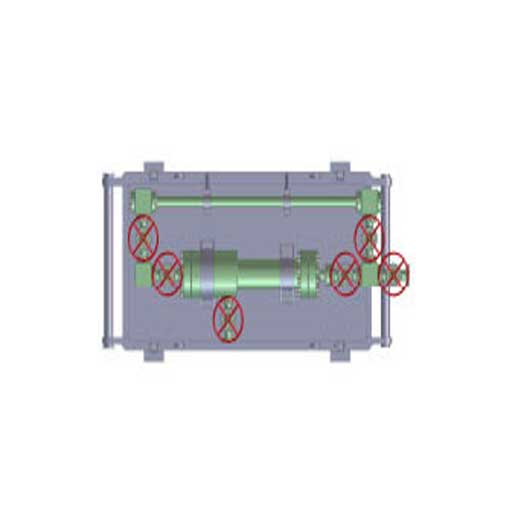

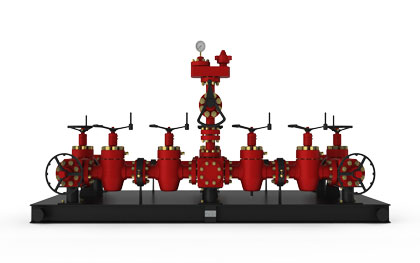

A manifold is a combination of multiple pipes. The manifold includes gate valves, pipelines, pipe fittings, pressure gauges, and electronic sensing, hydraulic control systems and other accessories. There are many types of manifolds that have different uses depending on the construction. Common manifolds include throttle manifolds, pressure manifolds, ring manifolds, kill manifolds, etc.

As a company that enjoys competiveness among other oil and gas equipment manufacturers,Saigao has its own manifold product series which consists of products such as choke manifold, cement manifold, filter manifold and frac manifold.

Provide an interface for production pipelines, submarine pipelines and oil wells;

Combine oil and gas for transport.

Distribute electricity and water pressure systems.

Support airfoil hubs, pipeline hubs and umbilical hubs.

Support and protect all piping and valve systems.

Provide a support point for the manifold module during the installation and recovery process; provide a support platform for the ROV during ROV operation.

The manifold and the well are completely independent in structure, and the oil well and the oil pipeline are connected to the manifold through the jumper. The management system consists of a manifold, a manifold support structure and an infrastructure. The manifold supports the junction between the structural manifold and the infrastructure.

The manifold consists of pipes, valves, control modules, flow meters, etc. On the chassis of the pipeline arrangement in the manifold, the oil and gas produced by the chassis well and the satellite well are collected by the manifold and piped to the platform. The injected water from the platform is distributed to each injection well through the manifold.

The manifold support structure consists of a frame made of pipe diameter and section steel. It functions to: provide guidance for drilling; provide a base for equipment installed under the underwater pipe; provide a carrier for underwater pipe sinking; protect the underwater pipe The exchange is not destroyed.

Most of the basic structure is in the form of a hydraulic anchor, and its structure is a large diameter steel structure.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română