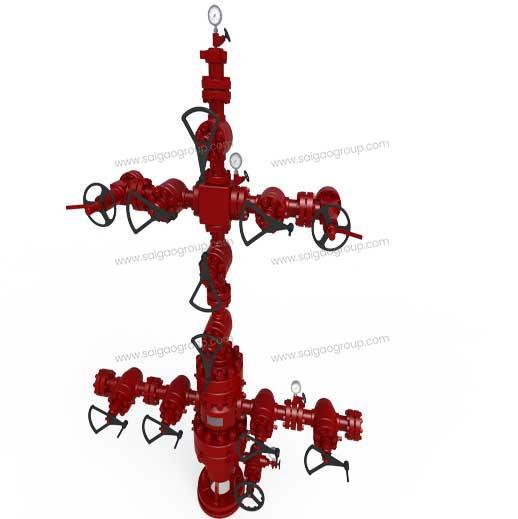

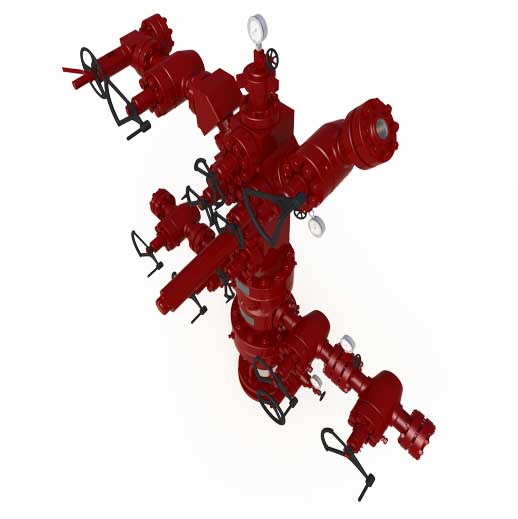

The X-mass tree is a wellhead device used to extract oil from wells and machine wells. It is the main equipment for controlling and regulating oil and gas production in the upper part of oil and gas wells. It mainly consists of casing head, tubing head and oil (gas) X-mass tree body.

The X-mass tree is a component that opens to the top opening of the well, including valves for measurement and repair, safety systems, and a range of monitoring instruments. The X-mass tree connects the production and outflow pipes from the downhole and serves as an important barrier to the isolation of the top of the well from the external environment. It includes a number of valves that can be used to regulate or prevent the production of crude oil vapors, natural gases and liquids from the well. The X-mass tree is connected to the production manifold system through a submarine pipeline.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română