In the development of the offshore oil and gas field, the submarine pipeline is the key component of offshore infrastructure. With the development of the oil and gas industry, flexible pipe (also known as a flexible pipe) is widely used in the development of offshore oil and gas fields. The composite hose can be used as a static pipeline (such as flowline) or dynamic pipeline (such as riser), which is widely used in production, injection, export and service pipelines. In the world, the number of composite hoses used as flexible risers plays an important role in the riser system.

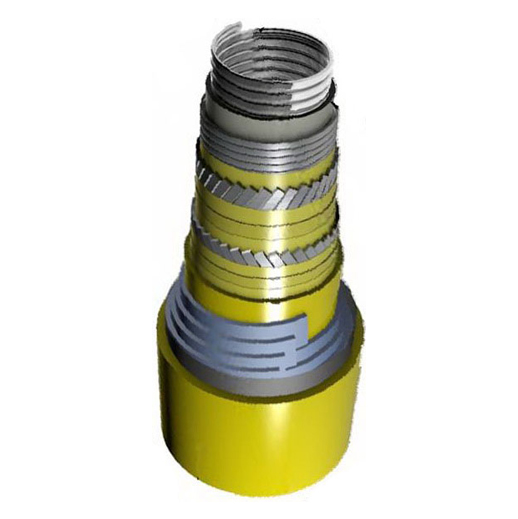

The composite hose can be divided into two basic types according to the structural type: UN bonded flexible pipe and bonded flexible pipe. This paper mainly introduces the non bonded composite hose products used in offshore oil and gas development abroad.

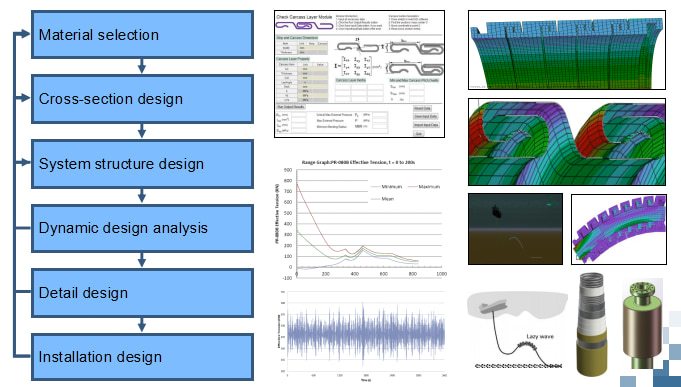

Compared with steel pipe, the unbonded composite hose has significant advantages as a subsea pipeline:

The installation is convenient and fast, and the expansion bend does not need to be installed separately, so the accuracy of installation and connection is low;

Loading and installation are safe, no need for large pipe laying vessel and low cost;

Good flexibility, seafloor terrain adaptability, long continuous length and few installation joints;

Good corrosion resistance;

| First oversea order of dynamic FP (6") |

| First dynamical composite FP in China (8") (E&P) |

| First large ID composite FP in China (12") (E&P) |

| First high T thermal insulation composite FP in China (8") (E&P) |

| First multiphase composite FP in China (8"&10") (E&P) |

| First company that get the award of API certification of offshore composite FP in China |

| First water-injection composite FP in China (4"& 6") (E&P) |

| First gas transporting composite FP in China (3") (E&P) |

| NOED established the R & D base of offshore composite FP |

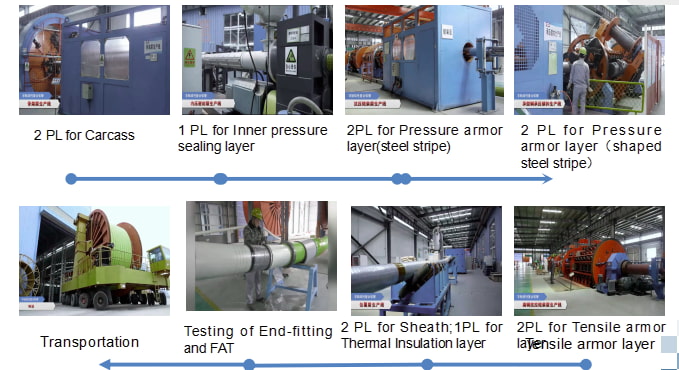

- Materials laboratory: more than 400 sets of test equipment, research and development of pipe polymer and metal materials.

- Prototype laboratory: more than 100 sets of equipment to verify and test the trial-produced and finished composite pipe.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română