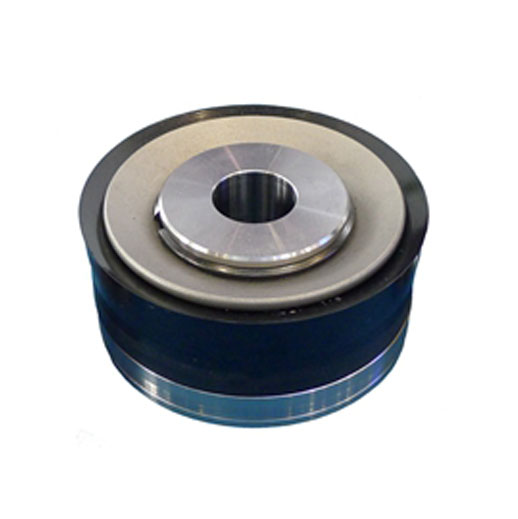

Saigao bonded rubber piston is forged from high quality rubber attached to a metal steel. Our bonded rubber piston is featured by excellent tensile strength and great durability. It can be applied in almost all drilling operation

The piston assembly is one of the main parts of the hydraulic end system of the mud pump, and it is also one of the wearing parts in drilling. The discharge pressure of the mud pump is generated by the piston assembly reciprocating linearly in the piston. The piston assembly is composed of piston core, rubber, circlip, pressure plate and so on. As a critical component among reliable drilling rig mud pump parts, the material of the piston core is 42CrMo, and the material of the piston rubber is nitrile rubber or polyurethane rubber. The material of the piston core is 42CrMo, and the material of the piston rubber is nitrile rubber or polyurethane rubber. The products produced by our company comply with API standards, have high tensile strength, chemical resistance and anti-wear properties, long service life, and can be used interchangeably with other pistons produced according to API standards.

Standard type

It is produced using imported nitrile rubber, and is suitable for ordinary drilling working environment with working pressure below 20Mpa, and the working temperature is not higher than 120C. Excellent wear resistance, chemical resistance, and long service life in ordinary drilling working environment

Enhanced type

The material is polyurethane rubber produced in the United States and Japan, which has excellent oil resistance and wear resistance. The working temperature is not higher than 120C, which is suitable for oil-based muds and working environments with high sand content below 35Mpa.

High temperature and high sulfur type

It is produced by hydrogenated nitrile rubber, suitable for high temperature, high pressure and high corrosion working environment. The working pressure is 75Mpa and the working temperature can reach 150C. Hydrogenated butadiene rubber is a rubber used in aviation. Used in the petroleum industry, hydrogenated nitrile rubber has abrasion resistance, oil resistance and chemical resistance, and its amine resistance and steam resistance are good. Especially in high temperature and high pressure working environment, other rubbers are quickly destroyed under the action of hydrogen sulfide, carbon dioxide, methane, steam and acid, but hydrogenated nitrile rubber shows good comprehensive performance.

The piston rod is also called the piston rod, which is the main part connecting the hydraulic end and the power end of the mud pump, and it is also one of the wearing parts. The big end is connected to the power end of the mud pump through a clamp to transmit power, and the small end is equipped with a piston to make reciprocating motion in the cylinder liner to generate pressure. The piston rod is forged from 42CrMo alloy steel, and the strength is increased after heat treatment. The product is numerically processed. The surface treatment is galvanized, nickel-plated, or decorative chromium-plated, which can meet different customer requirements.

Piston rubber is also called piston leather bowl, also known as vere rubber. It is the main component of the hydraulic end system in drilling mud pumps, and it is also one of the most used wearing parts in mud pumps. The piston rubber and valve rubber are rubber vulcanized products. The material of ordinary piston rubber is nitrile rubber. Polyurethane rubber can also be used to increase the working temperature range of rubber. Our company has developed a piston rubber with a unique formula, which can effectively improve the wear resistance and extend the service life compared to ordinary piston rubber.

The piston rubber cup for slurry is used for the piston of the mud pump. There are two types of assembled piston cups and integral pistons. The former is composed of oil-resistant rubber lip and nylon root. It is made of NBR and PU. The working pressure is 19.6 MPa. The working temperature is -20 ~ + 80 C.

The piston mud bowl of the drilling mud pump is composed of a lip and a root. The lip is generally made of NBR rubber or PU, and the root is generally made of nylon, PTFE, and rubber canvas. Tests have proven that pistons made of high-performance rubber-coated canvas have a longer service life.

But now pistons made of polyurethane with a strength greater than 60 MPa and a hardness greater than Shore 94 also have a longer service life. From the perspective of manufacturing and use, pistons made of polyurethane materials have more promotion value.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română