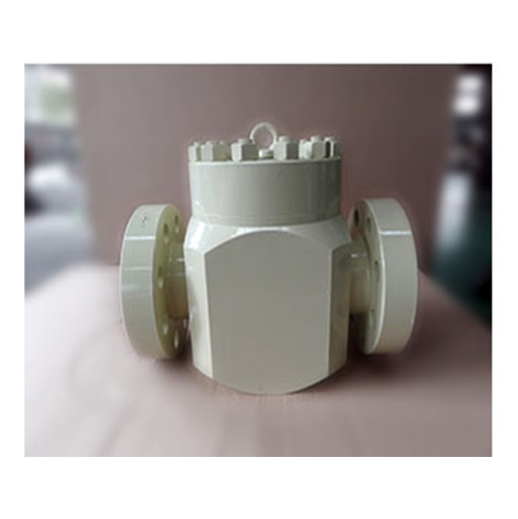

Saigao offers a full range of valves for drilling and production operations. Gate valves are designed and manufactured in accordance with API 6A latest edition PSL 1-4 while the robust, simple and reliable gate and seat design promotes ease of service with in-line maintenance.

Features include positive metal-to-metal sealing (gate-to-seat and seat-to-body), and stem packing that is chemically inert using spring energising rings which require no adjustment or plastic injection.

Stem packing can be replaced while the valve is under pressure and comes in API material classes AA through HH. Material for hydrogen sulfide and carbon dioxide service lies in accordance with NACE MR-01-175 latest edition. All valves are performance tested to PR2, with temperature ratings K through X up to 177°C (350°F).

Pressures up to 15,000 PSI for various API valve sizes

Metal-to-metal seals: Seals are stable, thermally insensitive and environmentally resistant; Utilised in the gate/seat, body/bonnet and stem/bonnet backseat

Selective backseat: Provides unparalleled safety during venting, lubrication and stem packing replacement; Allows stem packing replacement without removing valve from service

Slab gate: Assures smooth operation during extreme thermal cycles

Floating seats: Allows bi-directional use

Threaded packing gland: Transfers stem packing loads to the bonnet, protecting the bearing assemblies

No body penetration

Non-rising stem

Stem shear pin

In-line repairability

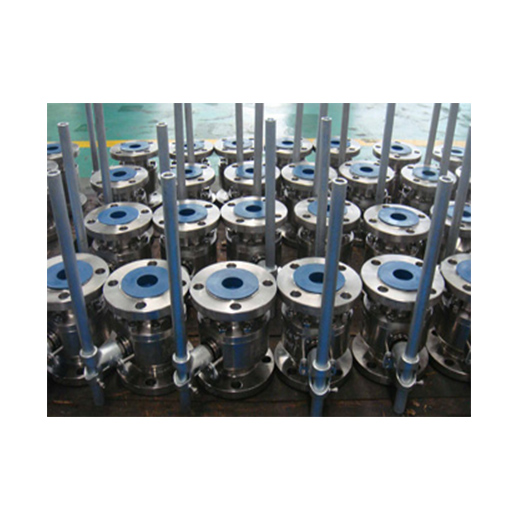

Today, people can find many types of valves in the market. Among them, the most typical manual valves will be the ones used in steam systems such as gate valve choke valve, check value and ball valve.

Valves are now widely applied in petrochemical, chemical production, thermoelectric industry, natural gas pipeline, coal chemical metallurgy, environmental protection transformation, food and medicine, municipal water affairs and real estate construction.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română