Mud pump parts (mud pump spares) are used on drilling rigs for the circulation of mud. These reciprocating pumps are suited for the process of drilling oil wells. We, at Saigao offer a wide selection of remanufactured, used and new drilling equipment for domestic and international drilling companies. We understand the needs of our clients and hence are better equipped to offer you the best drilling mud pump parts.

There are three basic different types of drilling mud pumps each with their own unique set of components and parts.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex: Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well's bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

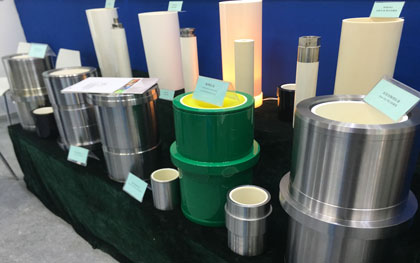

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

These pumps can be differentiated into single and double-acting pumps as per the completion time of the suction and drainage action in a cycle of the reciprocal motion of the piston. Mud pumps are available in a variety of sizes, in addition to the types, viz., triplex, duplex or quintuplex. The latest developments are hex pumps with 6 vertical pistons and quintuplex with 5 horizontal plungers.

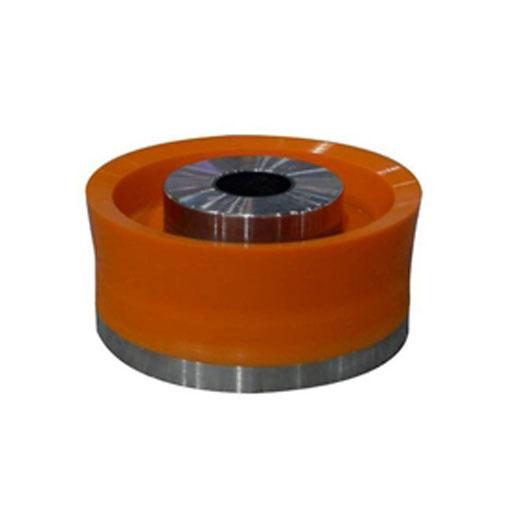

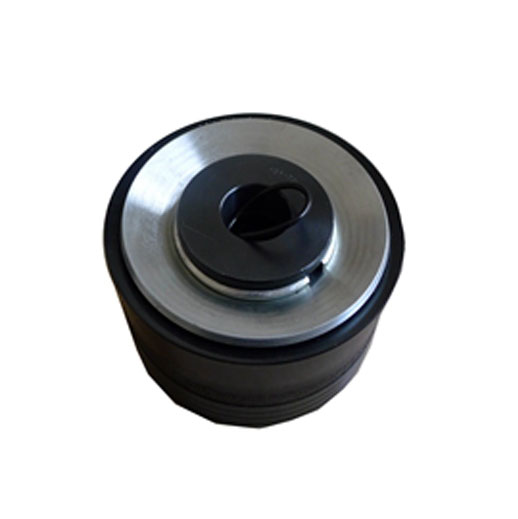

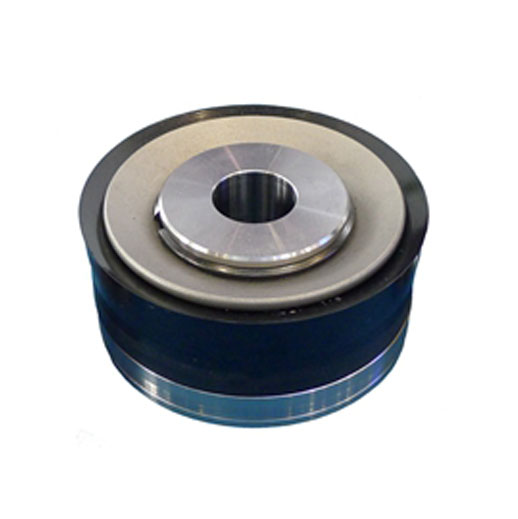

The fluid end provides valves, liners and pistons for the pumping process. These are high wear items requiring frequent replacement of parts. Severe vibrations caused by the pumping process necessitates a suction and discharge pulsation dampening component. The power end of the mud pump transitions the power of the driveshaft to the piston’s reciprocating motion. Parts of the mud pump include the plunger, piston, modules, housing, cover plus packing, piston rod, suction and discharge valves with their seats, stuffing box, pulsation dampener and glands.

Only when the right quality mud pump parts are purchased can the mud pump run smoothly. Saigao has a wide range of high-quality mud pump parts for sale, which will greatly extend the life of the mud pump.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română