Rubber Lining

Ultra rubber linings designed to withstand and resist abrasive, outperform in the harshest conditions.

Saigao Group rubber is a premier Manufacture of rubber lined products. Hand-lining of pipes, tanks, hoppers and other process equipment is our specialty.

Linings include:

Ultra natural rubber;

Neoprene;

Butyl;

Other types of rubber depending on the application;

Welding and grinding to Saigao Group Sep

Blasting to SA 2.5

Chemlok as a primer and dry

Glue 2 times

Rubber pattern cutting

to activate

Glue 2 times G18

Stick rubber to steel

Stitching and pull the air out

Trimming and finishing

We developed a new CR rubber for this customer with good wear resistance and weather resistance.

The product design life up to 2 years.

Total lining area is 140 ㎡

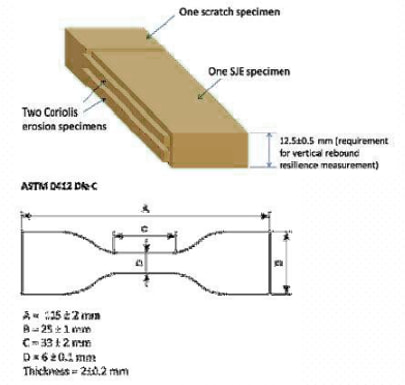

We created high-performance N41 rubber and CR rubber and sent them to the North

American laboratory. And now the sample is at the testing stage.

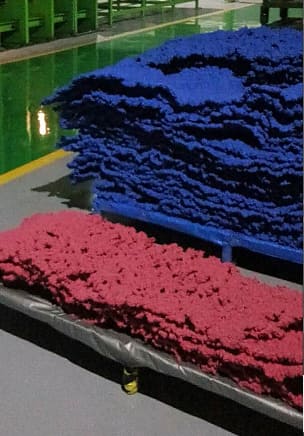

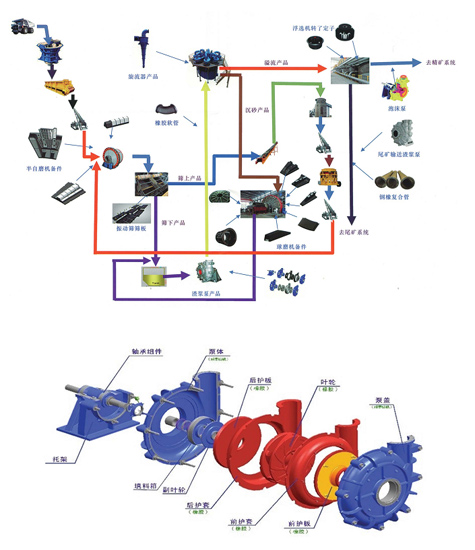

Saigao Group provide the latex mixing rubber for domestic customers to support their business expanding

Rubber valves for Anhui and Zhejiang customers:

The latex mixing rubber for the Cheng Du and Wu Han customer

We apply the Latex mining rubber for the customer to make the rubber valves and the impeller of the slurry pump. Saigao Group also supports them with a hot curing method to make the high-performance products and has been widely praised by the market.

The latex mixing rubber we provide to slurry pump customers has helped them extend the product life more than twice.

Capability : 3~5 Ton / Month

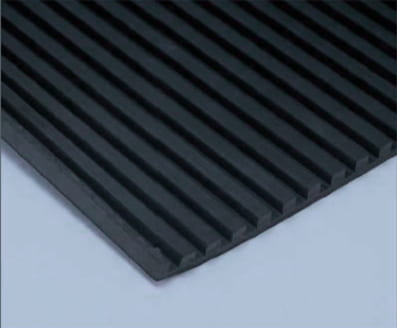

Saigao Group Ultra 36 is our star product. It has the top wear resistance performance and the rubber specifications can be compared with the world's top brands.

At present, the domestic customers are very interested in this rubber sheet and have begun to use it.

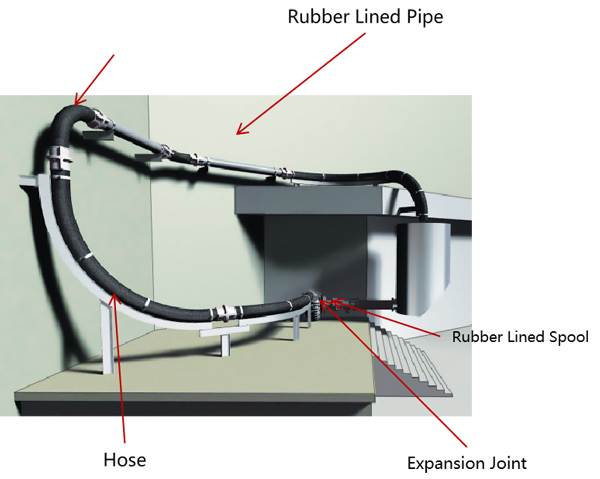

We rubber-lined spools and bends for the customer .

| Customer | Anhui |

| Location | Wuhu Hong Da |

| Year of Project | 2018.08 |

| Ling Area: | 195㎡ |

| Rubber applied | Saigao Group Ultra 36 12mm bos |

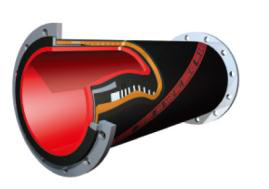

Built for suction and discharge applications, these robust hoses are manufactured with a heavy spring steel wire helix, designed to cater for high dynamic

Hard Wall Mining Hose is also suitable for heavy-duty industrial applications

Preformed Hose Bends are intended for use where space limitations demand a much sharper bend radius than can be achieved using a length of Hard Wall Hose

Steel wire is embedded to keep sharp and provide a suction capability

Extra rubber on outer arc can significantly increase the wearing life

Saigao Group's experience and expertise in the design and manufacture of custom-made material handling hose is second to none.

you are supported by the know-how of a Saigao Group team

Our specialty hose range incorporates slurry and chemical mining, tunnel boring and dredge application

A wide variety of preformed bends, reducers and T-pieces all of which are available with a versatile array of end types

Wear Indicator technology is a step towards improving both the safety and environmental impact of your site.

Saigao Group Ultra 36 is our star product. It has the top wear resistance performance and the rubber specifications can be compared with the world's top brands.

At present, the domestic customers are very interested in this rubber sheet and have begun to use it.

We rubber-lined spools and bends for the customer.

| Customer | Jiangxi |

| Location | Jiangxi |

| Year of Project | 2018.11 |

| Ling Area: | 10pcs |

| Rubber applied | Saigao Group Ultra 36 15mm bos |

We design and manufacture the rubber product for special application.

Natural raw material

Green technology

Cost-saving

The benefit of future generations

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română