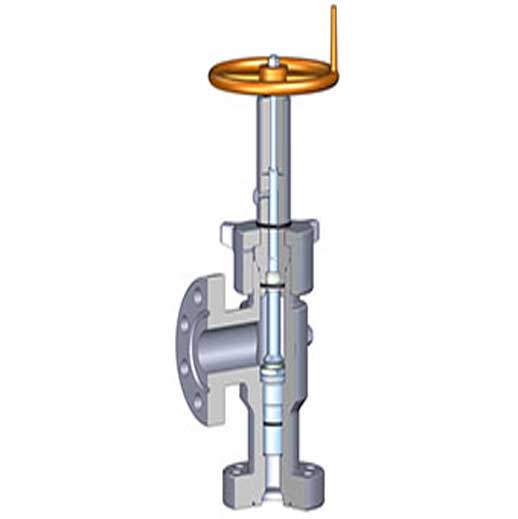

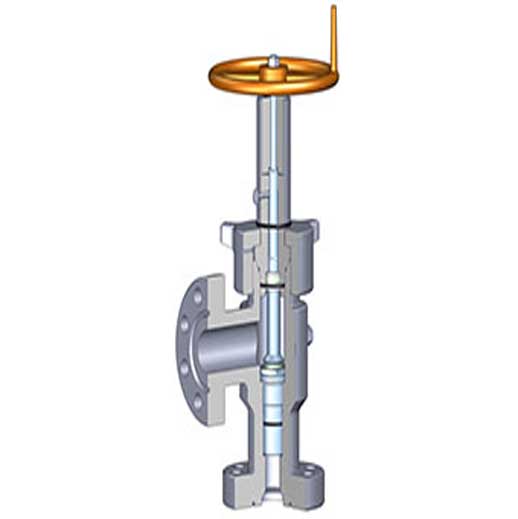

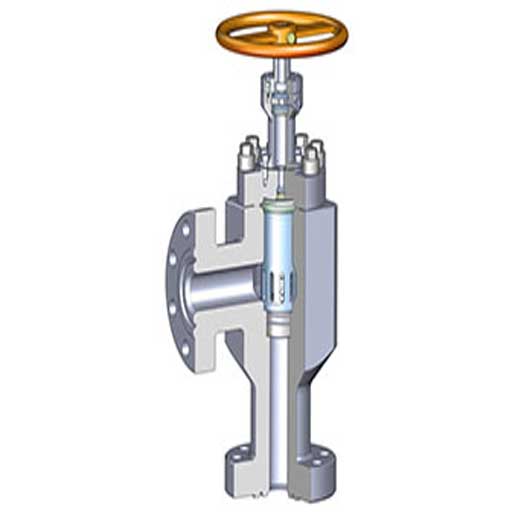

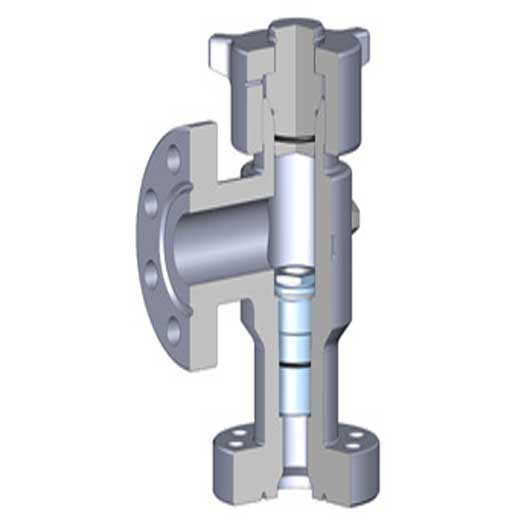

Choke valve is a valve that controls the flow of a fluid by changing a throttle section or a throttle length. The choke valve and the check valve are connected in parallel to form a one-way choke valve. The choke valve and the one-way choke valve are simple flow control valves. In the hydraulic system of the fixed pump, the choke valve and the relief valve cooperate to form three throttling speed control systems, that is, the throttle speed regulation System, return oil throttle control system and bypass throttle speed control system. The choke valve has no negative flow feedback function and cannot compensate for the instability caused by the load change. It is generally only used in applications where the load does not change much or the speed stability is not high.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română