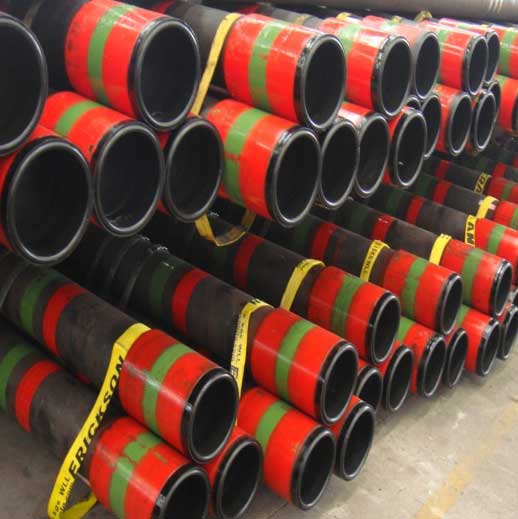

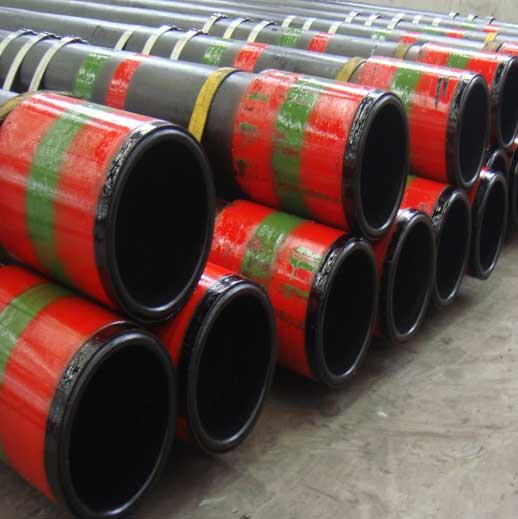

API 5CT casing is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to take place.

The cost of casing is a major part of the overall well cost, so selection of casing size, grade, connectors, and setting depth is a primary engineering and economic consideration. Saigao supply API 5CT standard casing pipe with assured quality and competitive price. Your honored customers' need is our goal to work for with our best efforts!

The oil casing is used to support the oil and gas well walls to ensure the normal operation of the entire well after the drilling process is completed. Each well is based on different depths of drilling and geology, using several layers of casing. After the casing is down, the cement is to be cemented. It is different from the oil pipe and the drill pipe and cannot be reused. It is a disposable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română