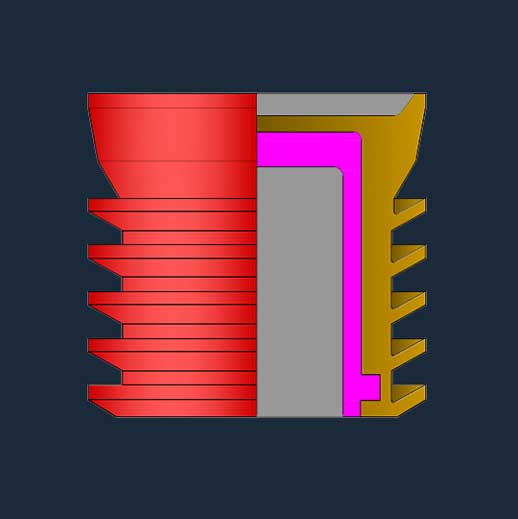

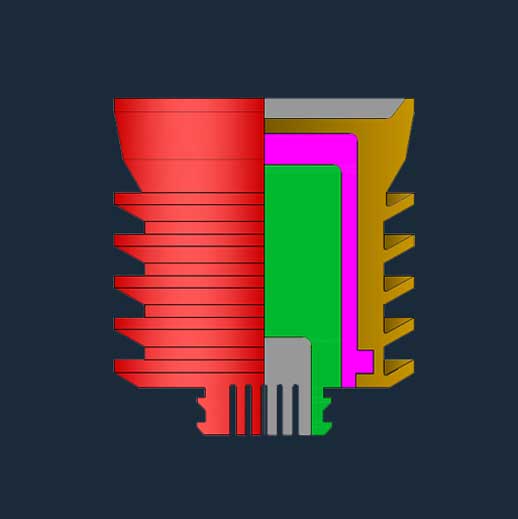

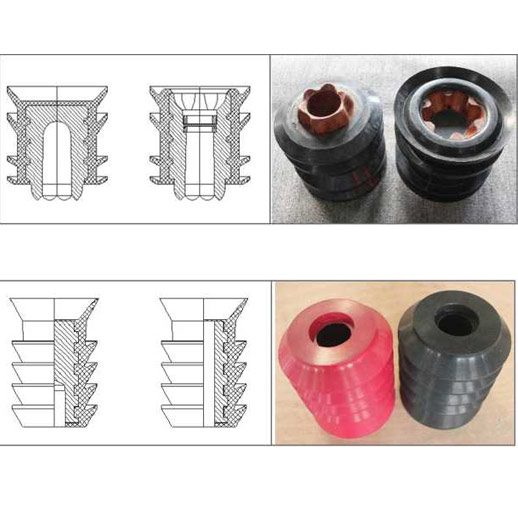

Saigao Rubber plug used to separate the cement slurry from other fluids, reducing contamination and maintaining predictable slurry performance. Two types of cementing plug are typically used on a cementing operation. The bottom plug is launched ahead of the cement slurry to minimize contamination by fluids inside the casing prior to cementing. A diaphragm in the plug body ruptures to allow the cement slurry to pass through after the plug reaches the landing collar. The top plug has a solid body that provides positive indication of contact with the landing collar and bottom plug through an increase in pump pressure.

A Cementing Plug is a separator that acts as a barrier between cement slurry and hydrocarbons present in a reservoir. This plug is made up of rubber and is also known as a wiper plug. The primary purpose of using the plug during cementing jobs is to prevent or reduce any contamination of hydrocarbons from cement slurry and maintain the predictable slurry performance.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română