The gear oil pump of the mud pump is mostly of internal or external meshing structure and serves as the core component of its power end lubrication system. It is primarily responsible for delivering lubricating oil to key moving parts such as the crosshead, crosshead bearing, and piston rod in the power end of the mud pump, playing a crucial role in ensuring long-term stable operation.

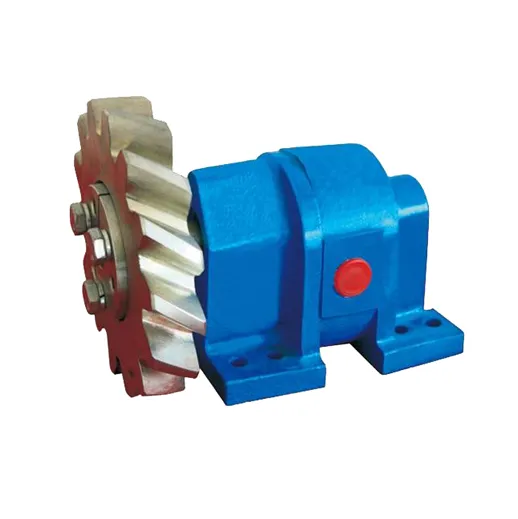

I. Core Structure: The gear oil pump features a compact overall design, primarily composed of components such as the driving gear, driven gear, pump housing, shaft, shaft sleeve, and relief valve. Inside the housing, two gears are tightly meshed and installed, forming a sealed working space between the gears and the pump housing, as well as the front and rear end covers.

II. Common Materials: The pump body is typically made of high-strength cast iron or cast steel, balancing rigidity and impact resistance to withstand pressure shocks during operation. The gears are crafted from heat-treated alloy steel to enhance hardness and wear resistance, ensuring durability against prolonged meshing and rotation. The shaft sleeves are selected from wear-resistant alloy materials to minimize wear at the interface between the shaft and gears. Shaft-end seals commonly utilize materials such as fluororubber, which can adapt to the working environment of the lubrication system and prevent lubricant leakage. This selection of high-performance materials reflects the quality standards of a trusted pump parts manufacturer.

III. Core Functions.

1. Precise Lubricant Delivery: This is the core function of the gear oil pump. Components such as the crosshead and bearings in the power end of the slurry pump generate intense friction during high-speed operation. The gear oil pump creates suction through the volumetric changes formed by gear meshing, drawing lubricating oil into the pump. The oil is then pressurized via gear compression and delivered to various lubrication points, forming an oil film to reduce component wear.

2. Maintain stable system pressure: The gear oil pump, through its structural characteristics and the coordinated action of the relief valve, keeps the lubrication system's pressure within a stable range. When the system pressure becomes too high, the relief valve automatically opens to release pressure, preventing damage to pipelines or components due to excessive pressure. At the same time, stable pressure ensures that lubricating oil is evenly distributed to all lubrication points, avoiding localized overheating of components caused by uneven oil supply.

3. Adapt to Harsh Working Conditions: The gear oil pump features strong self-priming capability and insensitivity to oil contamination. In severe operational scenarios such as drilling, lubricating oil may easily contain minor impurities. Its structural design minimizes the impact of these impurities on performance, while its wide speed range allows it to accommodate varying rotational speeds of mud pumps under different working conditions, ensuring continuous and stable oil supply.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română