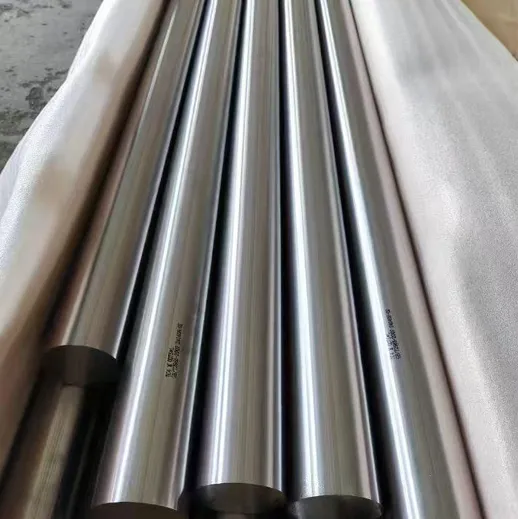

Non magnetic large-diameter bar material is a special steel used in the field of petroleum machinery to manufacture key components, with characteristics such as low magnetic permeability, high strength, and good corrosion resistance.

1. Non magnetic performance: The magnetic permeability of non-magnetic large-diameter bar materials is extremely low. For example, when the magnetic field strength of P530 non-magnetic steel bar is 16000A/m, the relative magnetic permeability μ r<1.005, the magnetic induction gradient ≤ 0.04 μ T, and almost no magnetic induction is generated, which can avoid interference with magnetic measuring instruments such as logging equipment while drilling.

2. High strength and toughness: This type of bar material has high yield strength and tensile strength, such as P530 non-magnetic steel bar with yield strength ≥ 850MPa, tensile strength ≥ 950MPa, elongation ≥ 30%. It is not easy to deform or fracture under high load, high pressure or impact, and can resist formation pressure and friction during drilling.

3. Corrosion resistance: It usually contains elements such as chromium and molybdenum, which can form a dense oxide film and prevent medium erosion. Like 15-15HS Max non-magnetic stainless steel, its pitting corrosion resistance equivalent is greater than 30, and it has good corrosion resistance to sulfuric acid, acidic oil and gas, etc.

4. Good processing performance: Some non-magnetic steel bars can be welded using various welding methods such as argon arc welding and laser welding. The weld strength is close to that of the base material, and the non-magnetic performance is stable. The cutting performance can be improved through processes such as high-temperature annealing, making it easy to process and manufacture.

15-15HS Max: High nitrogen strengthened austenitic stainless steel, commonly used for non-magnetic drilling boats, stabilizers, MWD shells, etc. with a yield strength of not less than 140KSI.

P550: It belongs to the non-magnetic steel series of high manganese, high chromium, and high nitrogen nickel, with high strength, wear resistance, and excellent mechanical properties. It is commonly used in large and medium-sized pressure drilling rods.

NMS 140: Non magnetic steel material, also widely used in the field of oil drilling.

1. Non magnetic drill collar: It is one of the main applications of non-magnetic large-diameter rod materials. The drill collar is mainly used to provide drilling pressure to the drill bit, keep the drill rod in tension, and use its high stiffness to straighten the drill bit and maintain the wellbore trajectory.

2. Sheath of measurement/logging instruments while drilling: It provides protection for the instrument, avoids external magnetic field interference with the measurement accuracy of the instrument, and ensures the accuracy of data.

3. Rotary directional drilling tool: During directional drilling, non-magnetic materials are required to ensure the normal operation of the tool, so that the drill bit can drill along the predetermined trajectory.

4. Stabilizer: Non magnetic large-diameter bar material can also be used as a non-magnetic stabilizer to maintain the stability of drilling tools, reduce drilling tool vibration and swing, and avoid affecting magnetic measuring instruments.

The production process of non-magnetic large-diameter bar materials usually strictly follows the API Spec 7-1 specification and SY/T 5144 standard, and can also comply with DS-1 specifications to ensure product quality meets the requirements of the petroleum drilling industry

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română