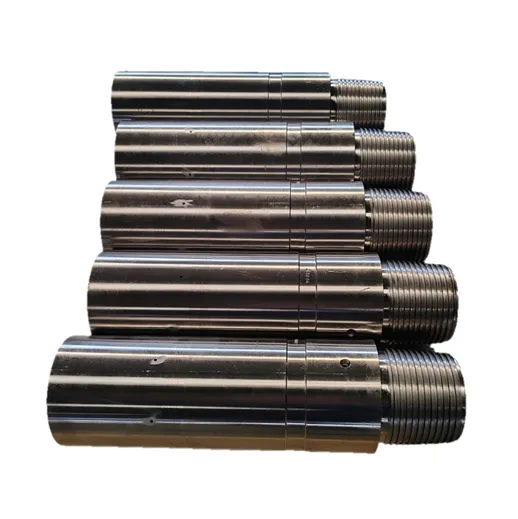

The piston housing of a drilling slammer is commonly found in hydraulic and hydromechanical drilling slammers. Often referred to as the housing barrel or stop housing, it is the core pressure-bearing component that houses the piston and coordinates the energy storage and impact actions. Its structural design directly determines the impact force and stability of the slammer.

1. Segmented Cavity Design

Taking a bidirectional slammer as an example, its piston housing is often divided into three sections: an upper stop housing, a balance housing, and a lower stop housing, which are sequentially connected to form the core of the integral shell. The upper piston, balance piston, and lower piston are correspondingly fitted inside. Some models, such as the YSZ hydraulic drilling slammer, also have a segmented structure with large and small cavities in the piston housing (lower housing). The sudden change in oil pressure and energy release are achieved through changes in the cross-sectional area of the cavities. Simultaneously, the inner walls of the upper and lower stop housings are designed with a necking structure to form a high-pressure zone. When the piston moves to this area, fluid flow is restricted, creating conditions for energy storage.

2. Sealing and Protection Configuration:

The inner wall of the piston housing has a trapezoidal limiting ring groove for embedding a sealing assembly consisting of a main sealing ring, a mud scraper ring, and a wear-resistant retaining ring. The mud scraper ring polishes the mandrel and adjusts the sealing pressure, the wear-resistant retaining ring prevents excessive compression of the seal, and the main sealing ring isolates the mud from the internal oil cavity through an interference fit. The inner circumference of the balance housing is also reinforced with a fixing ring to strengthen the sealing assembly and prevent oil leakage and seal failure under high temperature and pressure conditions downhole.

3. Auxiliary Functional Structure:

Some piston housings connect to other components via connecting joints. For example, the upper stop housing connects to the balance housing via an upper connecting joint. The joint has an oil filling hole for easy replenishment or replacement of hydraulic oil. In addition, the inner wall of the piston housing has a pre-reserved unloading chamber for rapid pressure relief when the piston reaches a designated position, triggering a shock action.

1. Pressure Bearing During Energy Storage:

When the drill string is pulled up, the mandrel drives the piston to move within the piston housing. The piston gradually enters the small cavity or high-pressure zone within the housing. At this time, the seal closes the main oil passage, and hydraulic oil can only flow through a small amount through the oil needle hole or drain groove on the piston, causing the oil pressure inside the piston housing to rise rapidly. The piston housing, made of high-strength material, withstands the high pressure, forcing the drill string to elastically elongate, thus converting mechanical energy into hydraulic energy for storage.

2. Energy Release Guidance During the Shock Phase:

When the piston moves to the unloading chamber or upper large cavity of the piston housing, the clearance within the cavity suddenly increases, allowing the previously pressurized hydraulic oil to flow freely instantly, causing a sharp drop in oil pressure. The piston housing, through this abrupt change in cavity structure, allows the piston to lose resistance, rapidly releasing the elastic potential energy of the drill string, driving the piston and mandrel to move at high speed, ultimately generating a strong shock force to release the stuck drill bit.

3. Precise Guidance of Piston Movement:

The high precision machining of the piston housing's inner wall provides a stable trajectory for the piston's reciprocating motion. For example, in a bidirectional shock absorber, when the upper and lower pistons slide within their corresponding stop housings, the housing wall prevents piston displacement and jamming, ensuring the continuity of the upward and downward impact actions. The balance housing, by constraining the balance piston, maintains pressure balance between the upper and lower oil chambers, preventing insufficient energy storage from affecting the shock absorption effect.

1. Bidirectional Hydraulic Shock Absorber

Equipped with upper and lower piston housings (stop housings), corresponding to the upward and downward impact actions respectively. The central balance housing balances the pressure in the upper and lower oil chambers, avoiding energy loss during unidirectional shock absorption, suitable for bidirectional unsticking requirements in complex downhole conditions.

2. YSZ Type Hydraulic Drilling jar

The piston housing (lower housing) is the core component generating the upward impact force. The storage and release of hydraulic energy are controlled by switching between large and small chambers, and the throttling resistance can be adjusted in conjunction with the piston's drain groove, adapting to unsticking requirements of varying sticking strengths.

3. ZSJ type mechanical hydraulic drilling oscillator:

Its pressure body can be regarded as a simplified version of the piston housing. The internal conical cavity cooperates with the conical piston. The flow path of hydraulic oil is controlled by the conical surface structure to achieve energy storage and oscillation. The structure is more compact and suitable for rapid oscillation operations during drilling.

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română