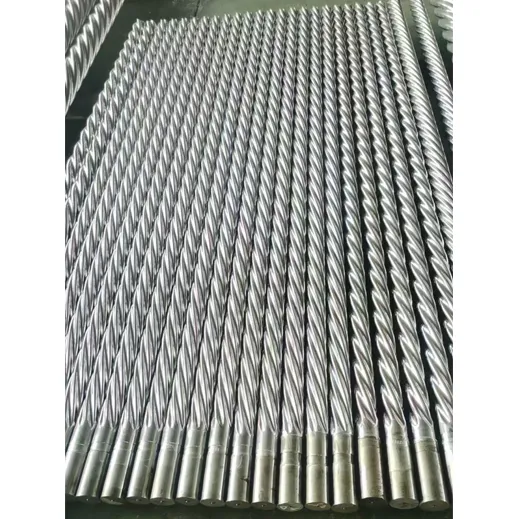

The non-magnetic screw stator is the core component of the power section in non-magnetic screw drills, often paired with the rotor to form the power mechanism. It is indispensable in directional drilling scenarios such as oil and gas well drilling and coal mine gas extraction borehole drilling. Below is a detailed introduction covering its core functions, key characteristics, commonly used materials.

1. Establishing the power foundation: It works in conjunction with the rotor to form a sealed chamber. When high-pressure mud pumped by the mud pump enters the chamber, it drives the rotor to perform planetary motion. This motion is then converted into axial rotation via a universal joint, enabling the drill bit to rotate and achieve rock drilling. Additionally, specially designed non-magnetic screw stators (such as those with an outer contour spiral) can generate upward force underground, facilitating the return of sand and rock debris with the mud, thereby reducing wear on the screw components caused by sand accumulation.

2. Ensuring measurement accuracy: In directional oil drilling, the drilling trajectory must be controlled using measurement sondes. However, conventional steel stators are prone to magnetization, which can interfere with the magnetic measurement signals of the sondes. Non-magnetic stators avoid self-magnetization, creating a stable non-magnetic environment for measurement instruments. This significantly reduces the impact on measurement accuracy, enabling more precise control of the drilling trajectory.

1. Strong magnetic stability: This is its core characteristic, requiring strict control over the material's permeability to ensure a consistently non-magnetic state under prolonged high-pressure and high-temperature downhole conditions, preventing any impact on surrounding measurement equipment due to magnetic variations.

2. Wear-resistant and corrosion-resistant: Drilling mud often contains hard particles such as rock cuttings and sand, and some mud is corrosive. The stator must possess excellent wear resistance to withstand particle erosion while also resisting mud corrosion, preventing cavity damage that could lead to seal failure.

3. High structural adaptability: The internal spiral line parameters of the stator must precisely match those of the rotor to ensure the sealing integrity of the sealed cavity, thereby guaranteeing power transmission efficiency. Additionally, its external structural design must align with the overall assembly of the drill string, such as some stators featuring a helical outer contour to accommodate downhole fluid circulation requirements.

Material selection must balance requirements such as non-magnetic properties, strength, and corrosion resistance. Different materials are suitable for different working conditions, as detailed below:

Material | Advantage | Applicable Scenario |

P530 Non-magnetic steel | Excellent mechanical properties, low magnetic permeability, moderate cost-performance ratio. | Suitable for most conventional oil drilling conditions, compatible with general-purpose non-magnetic motor drill assemblies. |

Beryllium copper alloy | Excellent non-magnetic properties, combined with good electrical and thermal conductivity. | High precision requirements for component dimensions, suitable for medium and low-pressure drilling scenarios with relatively moderate stress. |

Monel alloy | Exhibits strong corrosion resistance, is non-magnetic, and has high strength. | Suitable for deep oil drilling in harsh conditions with highly corrosive downhole mud. |

Austenitic steel | Exhibits excellent comprehensive mechanical properties and can be optimized for non-magnetic performance through process adjustments. | Suitable for mid-to-high-end drilling applications requiring a balance between cost and performance. |

0531-69959201

lqg18653457231

+86-18653457231

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

Professional customer service team, professional after-sale services create a comprehensive high-quality, advanced technology, reliable products, which gives you a strong sense of security.

Professionals, professional skills and precision oil and gas equipment insure that we can provide you with professional product customization service.

The best quality products, strict quality control system and good reputations established Saigao product's irreplaceable place.

Superb technical team with continuous technological innovation, closely follow the market's trend help you to create the highest performance products.

English

English  日本語

日本語  français

français  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Polska

Polska  română

română