Saigao Group has established its expertise in well construction through its innovative casing reamer shoe solutions, designed to optimize the wellbore conditioning process in diverse drilling environments. These specialized tools play a critical role in ensuring smooth casing runs while maintaining wellbore integrity, reflecting Saigao's commitment to advancing downhole tool technology.

Precision Engineering for Optimal Performance

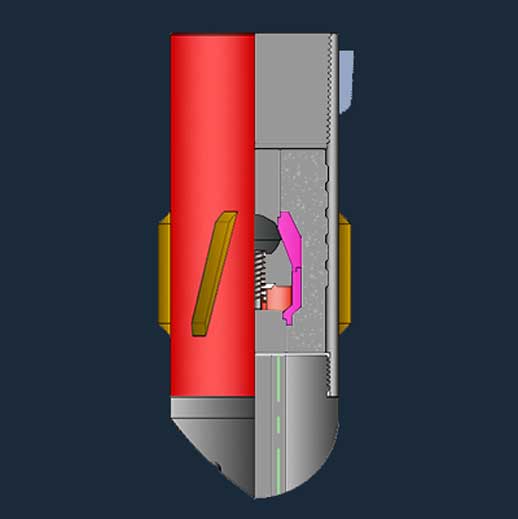

Manufactured using Saigao's advanced CNC machining centers and precision grinding equipment, the casing reamer shoe features an engineered cutting structure that combines durability with efficient material removal. The company's provincial technical center has developed proprietary cutting patterns that balance aggressive reaming action with controlled vibration characteristics, resulting in smoother operation downhole. These design features allow the tool to effectively condition the wellbore while preserving the structural integrity of both the formation and the casing string.

Adaptable Design for Varied Geological Conditions

Saigao's casing reamer shoe demonstrates remarkable adaptability across different formation types, from soft sediments to more consolidated rock layers. The tool's geometry and cutting structure have been optimized through extensive testing at the company's research facilities to handle challenging downhole environments encountered in oil, gas, and water well applications. This versatility makes the casing reamer shoe equally effective in conventional vertical wells and directional drilling projects, including applications in shale gas development and geothermal drilling.

Casing Reamer Shoe vs. Standard Guide Shoes

When comparing well construction options, Saigao's casing reamer shoe provides distinct operational advantages over conventional guide shoes. While standard shoes merely guide the casing into place, the reamer shoe actively improves wellbore conditions during installation. This proactive approach reduces the risk of stuck pipe incidents and minimizes the need for separate wellbore conditioning runs. The reamer shoe's ability to remove minor obstructions and smooth irregular borehole surfaces results in improved cement placement and ultimately enhances long-term well integrity.

Innovative Cutting Structure for Enhanced Efficiency

The casing reamer shoe incorporates Saigao's proprietary cutting technology developed at its municipal engineering research center. The carefully positioned cutting elements provide consistent reaming action while minimizing torque requirements, allowing for smoother casing runs. The tool's self-cleaning design prevents balling up in sticky formations, and its durable construction ensures reliable performance throughout the entire casing operation. These features are particularly valuable in extended reach wells where hole cleaning challenges are more pronounced.

Global Applications with Tailored Solutions

Saigao's casing reamer shoes have been successfully deployed in drilling projects worldwide, from conventional oil fields in Russia to challenging shale operations in China and water well projects in Africa. The company's engineering team works closely with clients to select or customize the most appropriate reamer shoe configuration for specific well conditions and operational objectives. This customer-focused approach, combined with Saigao's "Quality First" manufacturing philosophy, ensures reliable performance across diverse applications while reducing non-productive time during critical casing operations.

As drilling environments become more challenging and well integrity standards continue to rise, Saigao remains committed to advancing casing reamer shoe technology through continuous research and development. These tools exemplify the company's ability to combine practical field experience with technical innovation - qualities that have made Saigao equipment a preferred choice for operators seeking to optimize their well construction processes while maintaining the highest standards of operational safety and efficiency.