For decades, oil well choke valves have served as indispensable components in extraction operations, regulating fluid flow and protecting downstream equipment. Saigao Group has established itself as a trusted manufacturer of these precision instruments, combining engineering expertise with rigorous quality standards to deliver reliable solutions for global energy projects.

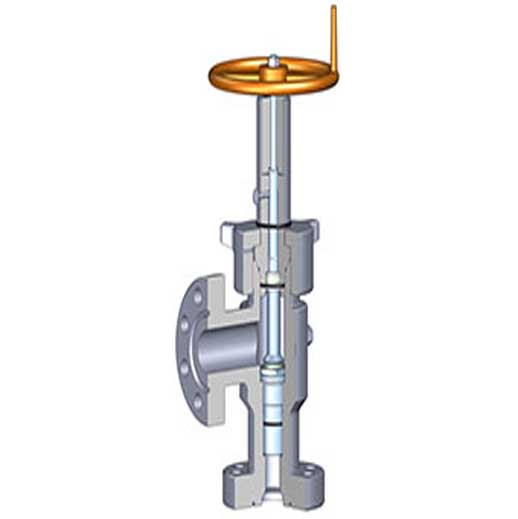

The primary function of an oil well choke valve is to maintain ideal flow rates while preventing reservoir damage—a delicate balance that demands exceptional engineering. Saigao's designs incorporate precisely machined trim components and durable sealing systems that withstand erosive well fluids. Unlike fixed orifices that require complete system shutdowns for adjustments, our adjustable choke valves enable operators to fine-tune production without interrupting operations. This capability proves particularly valuable in unconventional wells where flow rates fluctuate significantly during different production phases.

Operating in high-pressure, corrosive environments requires choke valves built to exacting standards. Saigao manufactures oil well choke valves using hardened alloys and specialized coatings resistant to hydrogen sulfide, carbon dioxide, and abrasive particulates commonly found in wellstreams. Critical wear components receive additional surface treatments to extend service intervals—an approach that reduces maintenance frequency by up to 40% compared to untreated alternatives, minimizing downtime for projects utilizing oilfield cementing equipment for sale. This durability ensures reliable performance whether installed onshore, offshore, or in arctic environments where equipment failures carry severe consequences.

Modern extraction techniques demand more sophisticated flow control solutions. Saigao's engineering team has responded with features like multi-stage choking for gas-heavy wells, preventing hydrate formation and equipment damage. Our oil well choke valves also integrate with digital control systems, allowing remote adjustments and real-time performance monitoring—capabilities becoming essential as operators adopt Industry 4.0 technologies. These innovations build upon our decades of experience supporting water well drilling, shale gas, and conventional oil operations across six continents.

While some operations still rely on manual valves or fixed chokes, modern oil well choke valves offer distinct advantages:

Fixed chokes lack adjustability, forcing operators to accept inefficient flow rates or undertake costly workovers. Manual valves require constant personnel attention, increasing labor costs and safety risks. In contrast, Saigao's engineered solutions provide precise, repeatable control with either manual or automated actuation. Our designs also minimize erosion hotspots through computational fluid dynamics optimization, addressing a common failure point in cheaper alternatives. When evaluated over a well's lifespan, these technical advantages translate to higher production efficiency and lower total ownership costs.

From Russia's Siberian fields to Brazil's pre-salt formations, Saigao Group's oil well choke valve operates in diverse environments. Our products help manage:

Unconventional shale gas wells prone to rapid flow variations

High-volume offshore producers requiring erosion-resistant designs

Mature fields needing precise water cut management

Backed by provincial-level technical centers, we provide application-specific solutions including cryogenic versions for LNG projects and compact designs for space-constrained platforms. This customization capability—paired with ISO-certified manufacturing—ensures each valve meets exact operational requirements while adhering to international safety standards.

Saigao Group's "Customer First; Quality First" philosophy drives constant refinement of our oil well choke valve offerings. Every unit undergoes stringent pressure and material testing before shipment, paralleling the protocols used for our renowned mud pumps and wellhead equipment. As energy extraction grows more technically demanding, we continue investing in advanced CNC machining centers and material science research—ensuring our choke valves meet evolving industry needs while maintaining the reliability that has made Saigao products preferred choices across global markets.