In the complex world of oil and gas extraction, efficient fluid distribution and control are crucial for maintaining smooth, safe, and high-output operations. At the center of this intricate network lies the oilfield manifold, a vital system that orchestrates the flow of fluids such as drilling mud, oil, gas, and water across various wellsite functions. As a key component in upstream operations, the manifold system plays a central role in both production and pressure management, often determining the overall efficiency and safety of a drilling or production site.

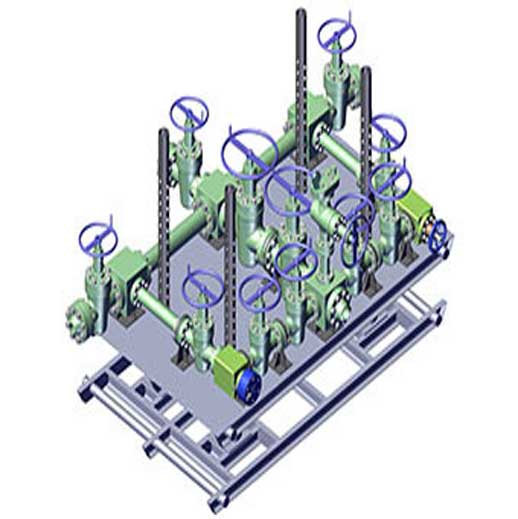

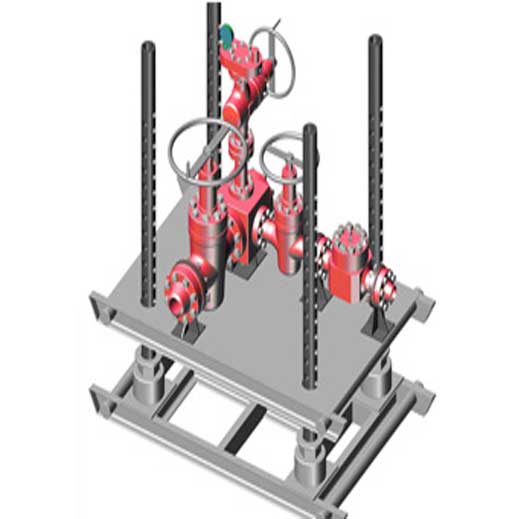

At its core, an oilfield manifold is a mechanical device designed to regulate and direct the flow of fluids from multiple wells or zones to specific destinations. Whether on the surface or installed subsea, these systems serve as collection and distribution points for production streams or high-pressure pumping. Their versatility allows them to operate in a wide range of applications, including choke and kill systems, cementing operations, testing procedures, and flowback handling.

Saigao Group, a company well-known for its expertise in oilfield equipment, offers highly engineered manifold systems that are used globally across diverse oil and gas environments. With a strong foundation in R&D and manufacturing capabilities, Saigao ensures that each manifold meets the performance and safety standards required in high-pressure field conditions.

The design of an oilfield manifold involves high-strength forged steel components, pressure-tested valves, and corrosion-resistant coatings to withstand aggressive environments and extreme conditions. Whether it's handling high-pressure injection during fracturing or managing flowback fluids rich in solids, these systems are engineered for reliability and longevity.

What sets Saigao's oilfield manifold apart is the attention to detail in pressure regulation, valve control, and component integration. By allowing operators to isolate sections, reroute flow, or relieve pressure instantly, these systems offer unmatched control, which is essential in avoiding overpressure accidents and optimizing fluid logistics.

To understand the true value of an oilfield manifold, it's helpful to compare it with basic piping configurations that may be used in less demanding operations:

Feature | Oilfield Manifold | Basic Piping System |

Flow Regulation | Precise, Multi-directional | Limited |

Pressure Control | High Accuracy, Real-time Adjustments | Manual or Fixed |

Maintenance Accessibility | Modular Design, Easy Isolation | Difficult |

Scalability | Easily Expandable | Rigid |

Application Flexibility | Suitable for High-Pressure, High-Volume Environments | Limited to Low-Pressure Uses |

This comparison highlights how oilfield manifolds deliver superior operational flexibility, reliability, and safety—especially in complex wellsite conditions where precision and control are non-negotiable.

As oilfield developments increasingly involve multi-well pads and complex well geometries, the demand for centralized fluid control grows. Oilfield manifolds enable operators to manage multiple well flows from a single point, dramatically simplifying the control process and reducing operational risks. Saigao's solutions are tailored for such setups, offering seamless integration with other wellsite systems including mud pumps, separators, and blowout preventers.

Their modular construction also allows easy transport and field assembly, which is critical for operations in remote or difficult terrains. From exploratory wells to full-scale production units, the oilfield manifold supports dynamic operational needs.

Safety is a paramount concern in the oil and gas industry, and manifold systems play an essential role in managing this risk. By allowing operators to isolate faults, regulate surges, and relieve pressure without shutting down the entire system, oilfield manifolds help prevent catastrophic failures. Additionally, they facilitate routine maintenance and testing without disrupting other well operations.

Saigao Group's commitment to precision engineering and quality manufacturing ensures that each manifold system performs under pressure as a global oil field equipment supplier. Their products are trusted in both domestic and international markets, reinforcing their reputation as a global leader in oilfield fluid control systems.