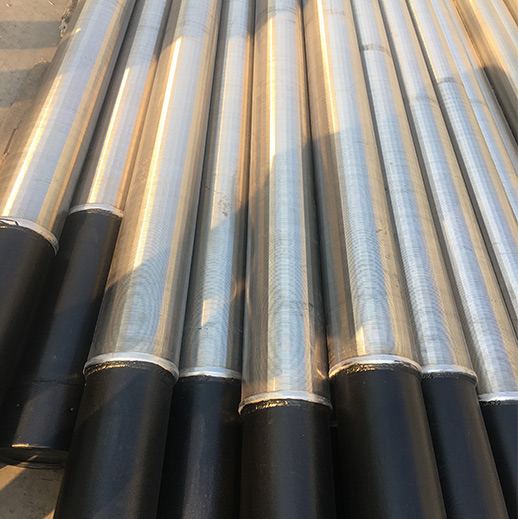

Saigao Group has established itself as a leader in manufacturing high-performance Wire Wrapped Screen, serving critical sectors including petroleum extraction, water well drilling, and mining operations. Our precision-engineered filtration solutions are designed to withstand the most challenging environments while maintaining optimal flow rates and particulate separation efficiency. The unique spiral design of our Wire Wrapped Screen features carefully spaced gaps formed by corrosion-resistant wires wound around a perforated base pipe, creating a robust filtration system that outperforms conventional alternatives in both longevity and performance.

At our provincial-level technical centers equipped with over 300 advanced NC machines and 4 machining centers, we produce Wire Wrapped Screen with unparalleled precision. Each screen undergoes rigorous quality control to ensure consistent slot sizes ranging from 0.1mm to 5mm, accommodating everything from fine sand filtration to coarse gravel packing applications. Our manufacturing process combines computerized numerical control technology with skilled craftsmanship, resulting in products that meet the strictest industry standards for dimensional accuracy and structural integrity. This commitment to manufacturing excellence has made Saigao Group a preferred supplier for projects across Russia, Brazil, Australia, and South Africa.

Understanding that different applications demand specialized solutions, we offer Wire Wrapped Screen in various high-grade materials including 304/316 stainless steel, super duplex alloys, and other specialty metals. Each material is carefully selected based on the specific chemical, thermal, and mechanical stresses anticipated in the field. Our engineering team works closely with clients to determine the optimal combination of wire profile, slot size, and base pipe configuration, ensuring maximum service life even in corrosive environments or high-pressure downhole conditions—key to maintaining operational synergy with oilfield cementing equipment for sale. This material expertise sets our filtration solutions apart in industries ranging from shale gas extraction to geothermal energy production.

The filtration market offers various solutions, but Wire Wrapped Screen from Saigao Group provide distinct advantages over traditional options. Compared to slotted liners that suffer from frequent plugging and inconsistent slot sizes, or punched screens that compromise structural strength, our wire wrapped design delivers precise gap control (with tolerances as tight as ±0.02mm) and uniform 360-degree filtration. Unlike pre-packed screens that are difficult to maintain, our screens offer easy cleaning and repair capabilities. These technical advantages translate to longer operational life, reduced maintenance costs, and better overall system performance - factors that explain their growing adoption across global energy and water resource projects.

From coalbed methane extraction in China to water well projects in Africa and offshore drilling operations in South America, Saigao Group's Wire Wrapped Screen have proven their reliability in diverse geographic and operational conditions. Our products play vital roles in water conservancy projects, bridge foundation construction, high-rise building developments, and non-excavation engineering. The municipal engineering technology research center at Saigao continuously develops new applications for our filtration technology, working with international partners to address unique challenges in petroleum, natural gas, and shale gas industries. This global perspective informs our product development and ensures our solutions meet the evolving needs of markets worldwide.

As a leading oil equipment manufacturer, Saigao Group remains committed to our "Customer First; Quality First" philosophy, offering not just superior Wire Wrapped Screen, but complete engineering support from design through deployment. As industries continue to demand more efficient and durable filtration solutions, we stand ready to deliver innovative products backed by decades of manufacturing expertise and a growing international presence.