In complex fluid systems across industries such as petroleum, chemical processing, water treatment, and mining, reliable flow control is critical. One essential component enabling precision and safety in such systems is the cylindrical plug valve. As a highly functional valve type, it plays a pivotal role in regulating the passage of fluids and gases with minimal leakage, low torque requirements, and high durability. Saigao Group, a well-established manufacturer of industrial equipment, offers high-performance cylindrical plug valves as part of its extensive product lineup, meeting global standards for reliability and efficiency.

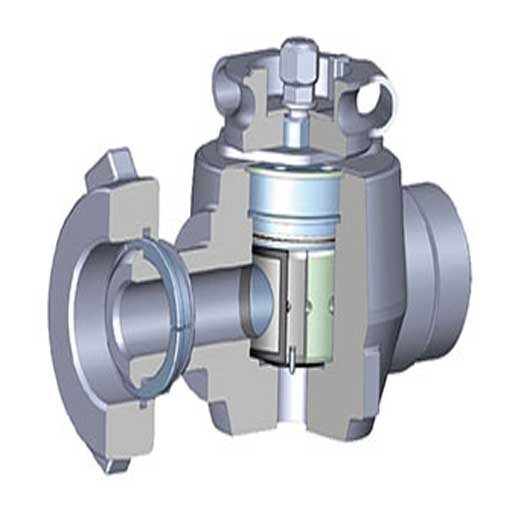

A cylindrical plug valve operates using a rotating cylindrical plug with a hollow passage that aligns with the flow path when in the open position. Its simple quarter-turn operation allows for quick opening and closing, making it a favored solution in systems requiring frequent operation or emergency shutoff capability. Due to its compact design, this valve minimizes the space required while still providing robust sealing properties and reduced friction.

Saigao's cylindrical plug valve is engineered using high-quality materials, precision-machined components, and undergo rigorous testing to ensure optimal performance under various temperature and pressure conditions. This design not only extends the valve's service life but also minimizes maintenance needs in demanding environments.

Cylindrical plug valves are widely used in pipelines that transport aggressive media such as crude oil, natural gas, and corrosive chemicals. Their design makes them particularly suitable for applications where bubble-tight sealing is a priority. In chemical plants and petrochemical refineries, Saigao's plug valves help ensure operational safety by providing dependable shutoff during routine maintenance or system upgrades.

Additionally, the valves' ease of operation and low pressure drop make them a top choice for high-cycle applications in oilfield workflows, complementing the efficiency of oilfield cementing equipment for sale. Their full-bore design ensures uninterrupted flow, which is critical in water conveyance systems and slurry pipelines, where efficiency and system longevity depend on minimal resistance.

Understanding the difference between cylindrical and tapered plug valves can help users select the right component for their application. The comparison below outlines key distinctions:

Feature | Cylindrical Plug Valve | Tapered Plug Valve |

Plug Shape | Uniform cylinder | Tapered cone shape |

Torque Required | Typically lower | Generally higher due to tighter fit |

Maintenance | Easier with simple disassembly | Can require more effort |

Sealing Mechanism | Sealing via alignment and lubrication | Relies on wedging for seal |

Ideal Applications | High-cycle, moderate pressure | High-pressure, infrequent operation |

As shown above, a cylindrical plug valve offers distinct operational advantages in settings that prioritize frequent valve actuation, ease of use, and maintainability over ultra-high sealing pressure.

In modern industrial systems, operational efficiency and safety go hand in hand. The cylindrical plug valve is a cornerstone of flow control architecture, offering engineers a reliable solution for regulating media flow with minimal operational complexity. Whether in upstream oil production, urban infrastructure, or chemical pipelines, these valves contribute significantly to process optimization and risk reduction.

As industries grow more automated and demanding, Saigao continues to innovate in valve technology, providing global customers with solutions that combine precision, strength, and reliability. The cylindrical plug valve is not just a product—it's a testament to engineering designed to meet the evolving demands of today’s fluid handling systems.