In the complex world of well completion operations, Saigao Group has developed specialized liner wiper plug technology that sets new standards for cementing efficiency and reliability. These precision-engineered tools play a vital role in ensuring proper zonal isolation while protecting downhole equipment during critical cementing operations.

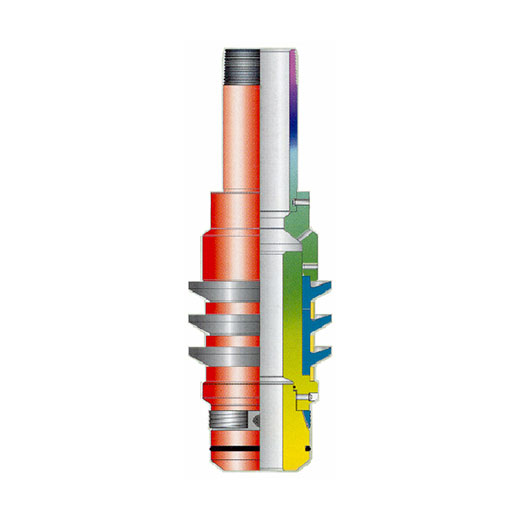

Saigao's liner wiper plug are manufactured using high-grade polymers and composite materials in the company's advanced machining centers. The plug design incorporates sophisticated sealing mechanisms that create a positive barrier between drilling fluids and cement slurry. This prevents contamination while ensuring complete displacement during the cementing process. The wiper element's unique profile has been refined through extensive testing at Saigao's research facilities to provide optimal sealing performance without excessive pump pressure requirements.

The versatility of Saigao's liner wiper plug system allows it to perform effectively in various well configurations, from conventional vertical wells to complex horizontal and multilateral completions. The plugs are available in multiple configurations to accommodate different liner sizes and cementing scenarios. This adaptability makes them equally effective in shallow water wells, deep oil and gas reservoirs, and specialized applications such as geothermal projects. The plug's robust construction ensures reliable performance even in high-temperature, high-pressure environments.

When comparing cementing tools, Saigao's liner wiper plug offers distinct advantages over traditional dart systems. While darts provide basic separation between fluids, the advanced wiper plug design ensures complete displacement and positive verification of cement placement. The plug's enhanced wiping action removes residual drilling fluid more effectively from the liner wall, improving cement bond quality that defines top-tier oilfield cementing equipment for sale. Additionally, the plug's positive latch mechanism provides reliable indication of proper placement, reducing uncertainty during critical cementing operations.

Safety is a fundamental consideration in the design of Saigao's liner wiper plug systems. Each plug incorporates multiple safety features including pressure-rated rupture disks and secondary release mechanisms. These innovations were developed based on field experience across global operations, ensuring reliable performance even in challenging downhole conditions. The plug's predictable disintegration characteristics eliminate concerns about drill-out operations, saving valuable rig time while maintaining well integrity.

As a leading oil equipment manufacturer, Saigao's liner wiper plug have been successfully deployed in oilfields worldwide, from conventional operations in Russia to challenging shale developments in China. The company's engineering team works closely with operators to customize plug configurations for specific well conditions and operational requirements. This consultative approach, backed by Saigao's "Quality First" manufacturing philosophy, ensures optimal performance across a wide range of applications while helping operators achieve superior zonal isolation.

As cementing operations become more complex and environmental regulations more stringent, Saigao continues to invest in advancing its liner wiper plug technology through ongoing research and field testing. These efforts demonstrate the company's commitment to providing reliable, efficient solutions that help operators achieve successful well completions while maintaining the highest standards of operational safety and environmental responsibility.