In the demanding environment of oil and gas extraction, flow regulation is not just a matter of efficiency — it's a matter of safety. At the heart of this critical operation lies the oil well choke valve, a device designed to control pressure, maintain flow stability, and protect downstream systems. Choosing the right choke valve can significantly improve well performance, operational control, and equipment lifespan. Saigao Group, a trusted name in oilfield machinery, offers high-quality choke valves engineered with precision and durability in mind.

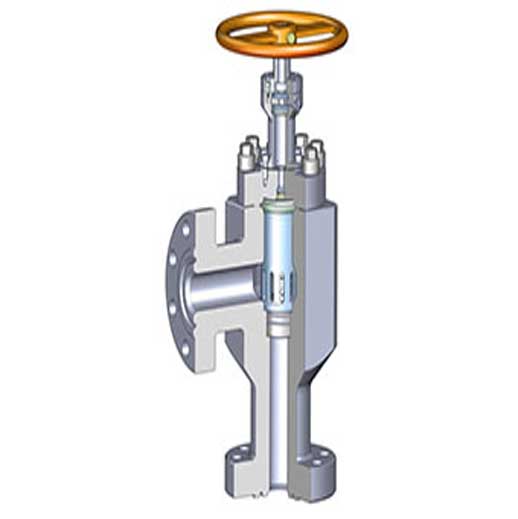

The oil well choke valve is a pressure-controlling component installed at the wellhead. Its primary function is to manage the flow rate of production fluids—oil, gas, or a mix—from the wellbore. By regulating the output, it protects the well from damage caused by excessive pressure, prevents formation collapse, and ensures safe transmission to surface facilities.

Unlike standard valves, choke valves are designed to operate under high-pressure, high-flow conditions. Saigao's choke valves, for instance, are built using advanced materials and CNC-machined parts that ensure resistance to erosion, corrosion, and pressure fatigue.

When evaluating which oil well choke valve is best suited to a particular drilling or production operation, several factors must be considered. These include the expected operating pressure, the type of fluid being transported, temperature conditions, and compatibility with existing infrastructure.

Saigao offers various choke valve configurations that cater to different operational needs — from adjustable to fixed chokes, and from manual to automated options. Adjustable chokes are ideal for wells with fluctuating production rates, while fixed chokes provide stability and are easier to maintain.

Choosing the Right Design

Criteria | Fixed Choke Valve | Adjustable Choke Valve |

Flow Control | Set flow rate, requires change-out | Flow rate can be changed in-place |

Maintenance | Simple design, fewer moving parts | Requires more maintenance |

Operational Flexibility | Limited | High, suited for variable wells |

Cost | Lower upfront and maintenance cost | Higher cost, but more versatile |

Application | Stable wells, long-term production | Exploration, early-stage wells |

This comparison makes it clear that the choice between a fixed or adjustable oil well choke valve depends on your operational goals. For stable, high-volume production, a fixed choke is efficient and low-maintenance. On the other hand, an adjustable choke is best suited for early well life or when production behavior is unpredictable.

Importance of Material and Pressure Ratings

Oilfield environments are harsh. Abrasive materials, corrosive gases, and high pressures are common. That’s why material selection is critical in choke valve performance. Saigao’s valves are typically made from high-strength stainless steel or nickel alloys with coatings designed to resist wear and chemical attack.

Understanding your well’s pressure profile and fluid composition will guide the correct pressure class and trim type required for long-term valve reliability. Always consult technical specifications to ensure the choke valve can handle both the maximum and average operating conditions.

Saigao Group’s deep expertise in oilfield machinery design and manufacturing makes it a reliable provider of high-performance oil well choke valves. With more than 300 advanced machining systems and several research centers dedicated to fluid equipment, Saigao ensures tight quality control and innovation at every stage.

In addition to durable products, Saigao provides engineering support to help customers select the ideal choke valve configuration as reliable oil and gas equipment suppliers. Whether you're managing shale gas, conventional oil, or complex offshore wells, Saigao’s choke valves deliver dependable performance that aligns with global safety standards.